The Kingsweld Product

Introduction

A KingsWeld exothermic weld metal consists of copper oxide, aluminium and flux in a granular (powder) form.

Each weld metal is packed into a plastic container. Different connections require differing weld metal sizes and so each container is marked with the weld metal size (grams).

These sizes are detailed in the table (right), which also provides our standard packaging information.

| DESCRIPTION | PART NO. | ||

|---|---|---|---|

| Weld Metal 15 | #015 | ||

| Weld Metal 25 | #025 | ||

| Weld Metal 32 | #032 | ||

| Weld Metal 45 | #045 | ||

| Weld Metal 65 | #065 | ||

| Weld Metal 90 | #090 | ||

| Weld Metal 115 | #115 | ||

| Weld Metal 150 | #150 | ||

| Weld Metal 200 | #200 | ||

| Weld Metal 250 | #250 |

Weld Metals

The weld metals are packed into plastic inner cartons, each of which contains metal discs, a moisture absorbing sachet and a box label, clearly identifying size, quantity and batch information.

The weld metal container has two compartments. The main weld metal is under the green cap and the starter powder is under the red cap.

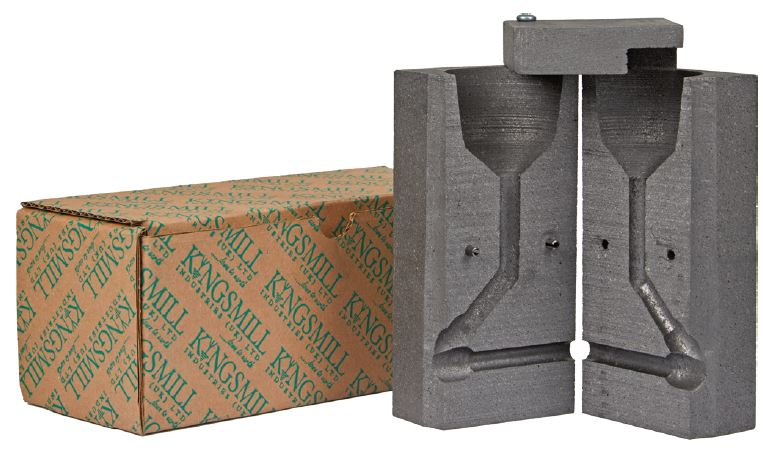

Moulds

The KingsWeld exothermic mould is manufactured from high quality graphite. This lends itself to easy machining, as well as being able to withstand the high thermal and mechanical shocks produced during the exothermic welding process. Heat obtained in such reactions is in excess of 2000°C.

Our moulds are designed to have an average lifetime of 50 to 60 connections. But, if treated with care, it is possible to obtain a significantly longer life.

Graphite is both brittle and soft, therefore it is important that the operator takes care whilst handling the product.

Worn-out or damaged moulds should not be used.

Each mould has a nameplate, detailing the connection type, part code and the correct weld metal size to be used.

The KingsWeld range of moulds can found HERE. If you do not see the connection, configuration or size of conductor that you require, please contact our sales office who will be pleased to assist you.