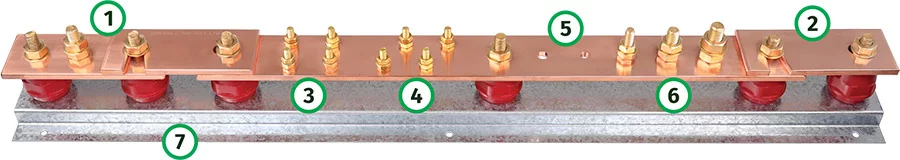

Earth Bar Design

Components of an Earth Bar

Understanding and designing Earth Bars should never be a difficult task.

Kingsmill are on hand to aid you with this design process to cater for any size, configuration or finish of Earth Bar. The sample Earth Bar, below, contains many elements that Kingsmill consider when designing special Earth Bars.

1: Outgoing Way

Outgoing ways enable the earth connection to be isolated from the test link.

This enables the test link to operate without the need to loosen the earth connection to the Earth Bar.

3: Parallel Fixings

Parallel fixings are typically used when there are space restrictions impacting on the installation of the Earth Bar.

By using parallel fixings, the length of an Earth Bar can be significantly reduced. Also, parallel fixings can be used to accommodate cable lugs with two fixing holes.

5: No Fixings

Earth Bars can also be supplied without fixings. Options include punched holes, tapped holes or plain bar.

7: Bases

Kingsmill supply all Earth Bars on metallic bases. All standard stock Earth Bars up to 12 ways (standard, single and twin link) are supplied on powder coated bases. Kingsmill can also supply galvanised and hot-dipped galvanised bases for use in external or more humid environments eg coastal.

2: Standard Link

Standard test links are supplied on all Kingsmill Earth Bars unless outgoing ways are requested.

4: Staggered Fixings

Like parallel fixings, staggered fixings are typically utilised to lower the overall length of an Earth Bar in the event of space restrictions.

Parallel fixings can also be spaced to allow cable lug connections to be made from both sides of the Earth Bar.

6: Fixings

Kingsmill Earth Bars are supplied with M10 brass fixings as standard.

We can also supply fixings of different size and material. These include M4 – M16 sizes and stainless steel, phosphor bronze and BZP materials.

Fixing Centres

Kingsmill Earth Bars are supplied as standard with a minimum 35mm distance between fixing centres. Typically, this allows for up to a 185mm² cable lug to be installed on adjacent fixings. Larger cable lugs may require larger fixing centre’s to accommodate wider cable lug palms.