Making a KingsWeld Connection

The following describes the exothermic welding process

Before making a KingsWeld connection:

- Always wear proper clothing, gloves and safety glasses when exothermic welding

- Read the general safety instructions and the positioning of conductors sheet supplied with each KingsWeld mould to familiarise yourself with the procedure you are going to perform.

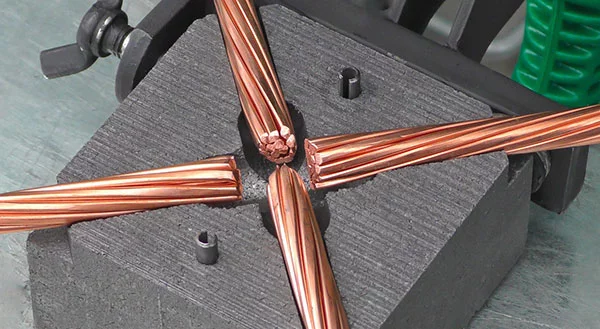

- Make sure the conductors that are to be welded are dry, dirt-free and clean.

- Use the wire brush to clean the conductor surfaces being placed inside the mould – the cleaner the surface the better the connection will be.

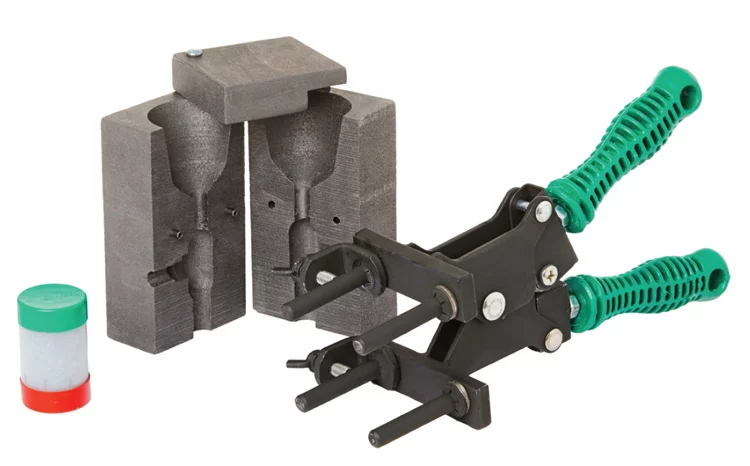

- Attach the handle clamp to the KingsWeld mould and check it will open & close freely.

- Make sure that the KingsWeld mould is dry and moisture free. The best way to do this is by pre-heating the mould with a blow torch or by making a test connection.

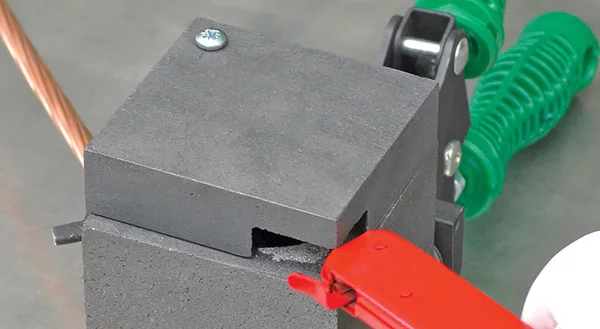

Position cleaned conductors in the mould

Make sure the mould is dry & moisture-free by pre-heating or making a test connection.

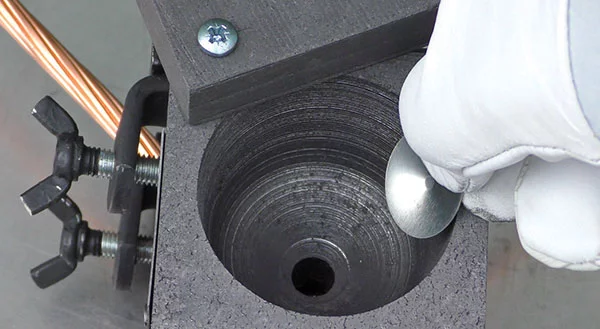

Place the metal disc in the bottom of the mould crucible

Discs are supplied with the weld metal.

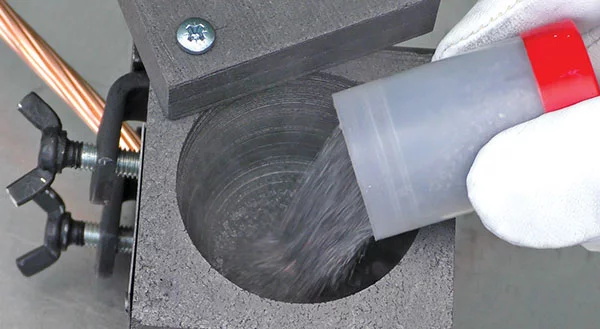

Pour weld metal into the mould crucible

Weld metal is under the green cap. Pour all weld metal into the crucible.

Add starting powder to the weld metal

Starting powder is under the red cap. Pour on top of the weld metal. Add a small amount of starting powder to the lip of the mould – to aid ignition – and close the lid.

Use flint gun to ignite starting powder

Pull flint gun away as soon as trigger is pulled to keep from fouling flint gun.

CAUTION: do not place any exposed body part directly over lid or in front of opening.

After approximately 20 seconds open the mould with the handle clamp

Knock off slag with the mould cleaning brush handle and clean the mould thoroughly, including the crucible and lid.