Fittings Guide

Introduction

Lightning Protection Accessories and Fittings

Once the type of Lightning Conductor has been chosen, it is important to consider how to fix/secure this to the structure being protected. The Kingsmill range includes fixings for both roof and wall and are designed to suit most applications, as well as materials.

DC Clips, Saddles, Clips, Hold Fasts, Adhesive Clips, Bimetallic Connectors, special roofing fixings etc.

Materials used include: high copper content alloys, aluminium and UV resistant plastics.

When choosing a suitable connector for your lightning protection design it is important to ensure that:

- The connector is mechanically robust.

- The connector is selected according to its application.

- The connector is rated for its application.

- To avoid bimetallic corrosion – use a bimetallic connector (do not connect bare copper directly to bare aluminium, or have water run-off from copper, fall onto aluminium).

Galvanic corrosion – happens when there is a potential difference between dissimilar metals:

- When the materials are in contact in the presence of an electrolyte, corrosion occurs. One metal becomes the anode, the other the cathode. The anode will tend to go into solution and therefore corrode. The electrolyte can be water with impurities from the air.

- In the instance of water run-off from copper – the water carries fine copper corrosion particles which, when they drip on to aluminium or zinc, may result in corrosion. The direct contact of the dissimilar metals in not required for corrosion to occur in such a case.

From BS:EN 62305 . . .

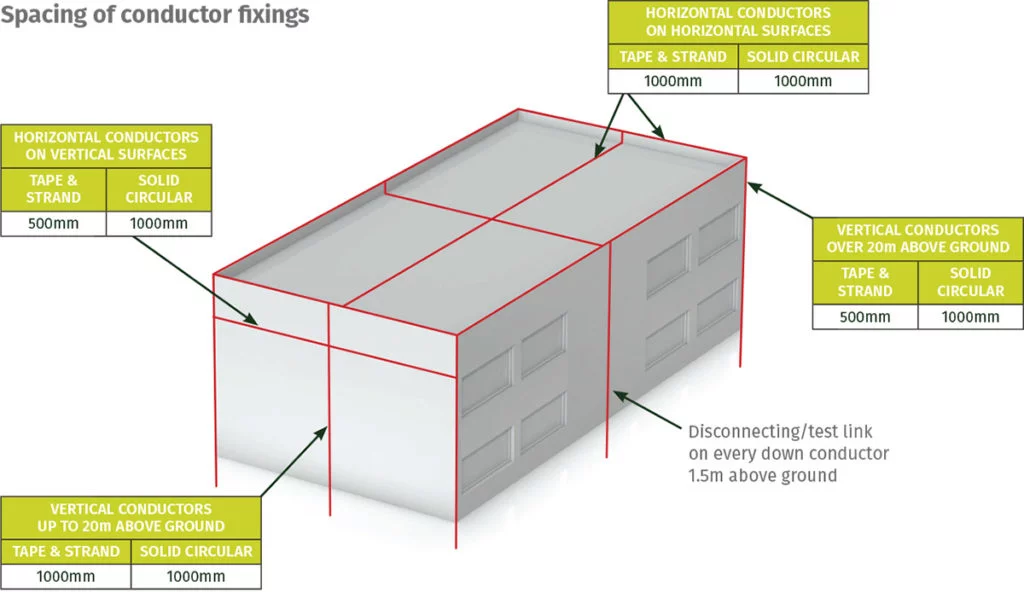

BS:EN 62305-3 contains guidance on the quantity of fixings to be used through specifying minimum distances and usage.

Lightning down conductors should each have the provision of a test or disconnecting link to separate the above and below ground conductor networks during testing.

Conductor fixings should be placed taking into account the minimum spacings recommended within BS:EN 62305, as well as practical considerations associated with building geometry.

Most Kingsmill connection components have been tested to BS:EN 62561-1 – Lightning Protection Components – requirements for connection components. They have passed both environmental ageing and 100kA impulse current testing and rated H.