MOULD CARE AND INSPECTION

Introduction

The Kingsweld mould is important to the exothermic welding process not only in that a) it shapes the final weld, but also through taking good care of the mould, it leads to a good quality exothermic welded connection.

KingsWeld moulds are manufactured from high quality graphite which, by nature, is soft and needs to be handled with care in order to get the maximum lifetime.

Mould care guide

- Always clean the mould after every weld

- Only use KingsWeld cleaning equipment (soft brush) to clean the mould

- Keep the mould dry and away from moisture

- Do not hit or drop the mould

- When not in use, keep the mould in its packaging for protection

- Try not to hit the edges of the mould with the conductors to be connected

- Never use a wire brush to clean the mould

- Always use the correct weld metal size, tools and handle clamps

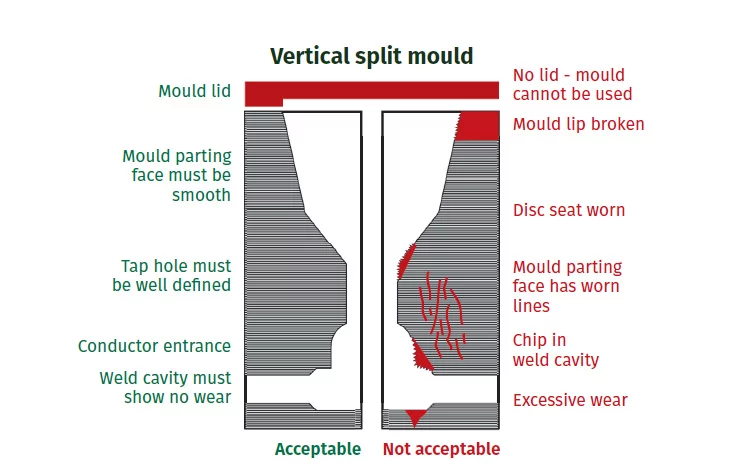

Mould inspection

- Handle the mould with care.

- Mould must be dry with fixed lid.

- Identification plate must be attached.

- Mould faces must be smooth, so they seal properly.

- Mould steel disc seat must not show signs of wear, chips or gouges (steel disc must seal the hole properly to prevent weld metal entering the weld cavity prior to welding).

- Tap hole must be well defined.

- Weld cavity must not show signs of wear, chips or gouges (conductors must have a 3mm gap between them prior to welding, fit snugly and not be loose in the mould).