Product Information:

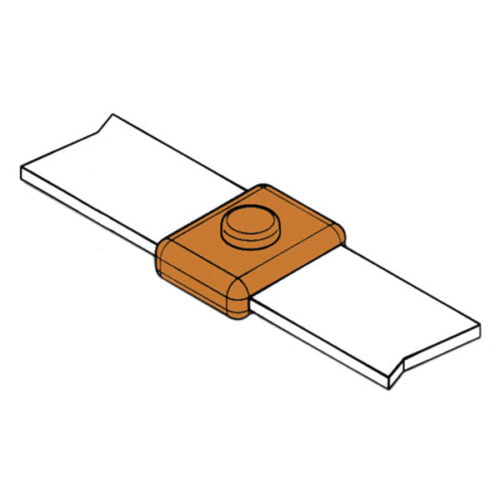

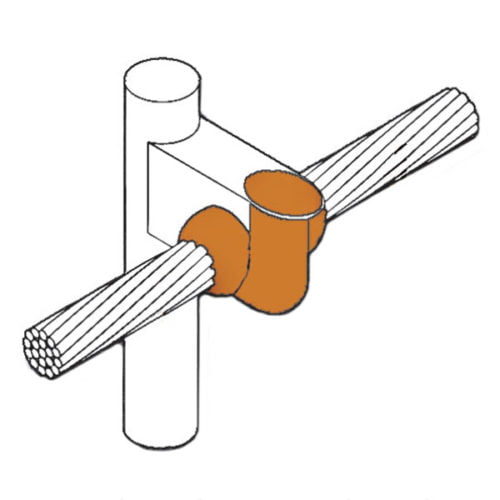

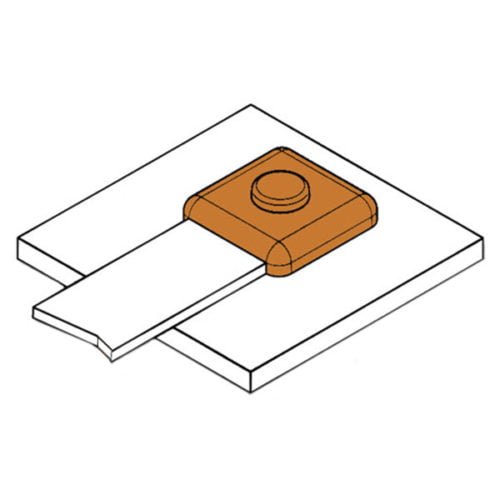

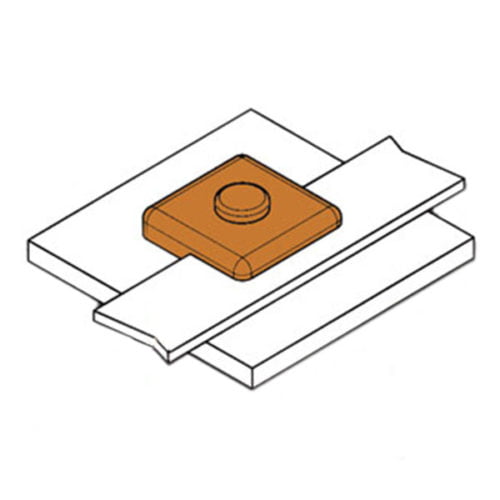

Kingsmill Industries offers Hammer Dies to assist with your KingsWeld Exothermic connection and rail applications. Use of the hammer die allows the normally circular section of the conductor to be hammered flat at one side. The newly created flat surface then fits flush with the rail allowing a good quality conductor to rail connection

Features:

Available in different sizes ranging from 35 mm² to 240 mm²

Before making a KingsWeld connection:

- Always wear proper clothing, gloves and safety glasses when exothermic welding.

- Read the general safety instructions and the positioning of conductors sheet supplied with each KingsWeld mould to familiarise yourself with the procedure you are going to perform.

- Make sure the conductors that are to be welded are dry, dirt-free and clean.

- Use the wire brush to clean the conductor surfaces being placed inside the mould – the cleaner the surface the better the connection will be.

- Attach the handle clamp to the KingsWeld mould and check it will open & close freely.

- Make sure that the KingsWeld mould is dry and moisture free. The best way to do this is by pre-heating the mould with a blow torch or by making a test connection.