Product Information:

The thread must be rolled after plating to ensure maximum copper coverage over the threads. Rolled threads are also stronger than cut threads.

Features:

Material: Pure copper molecularly bonded on to a steel core

Standard: BS:EN 62561-2, BS 7430

Copper Thickness: 254 microns (minimum)

More Information:

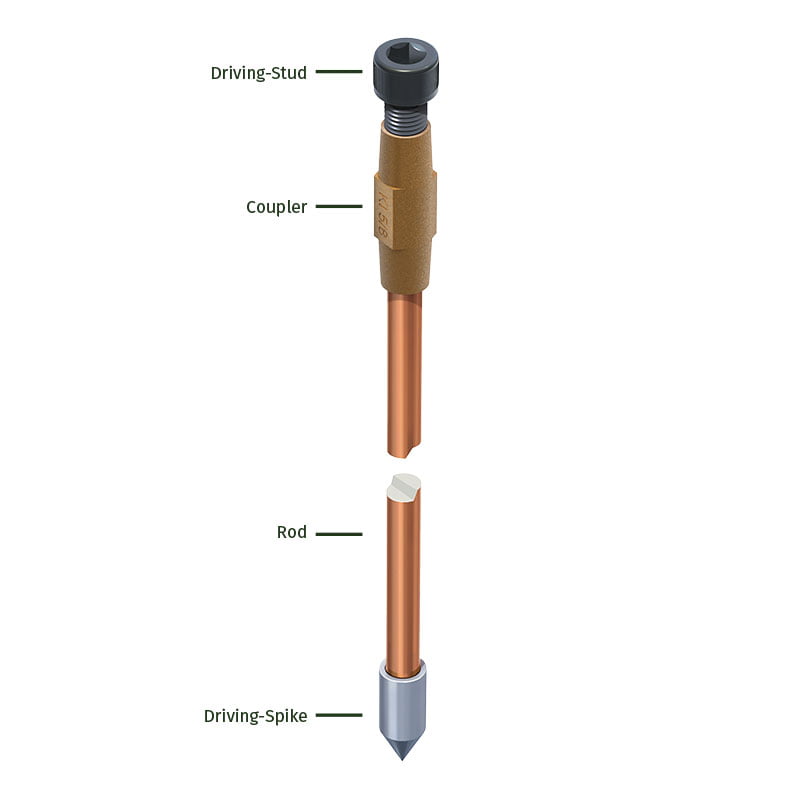

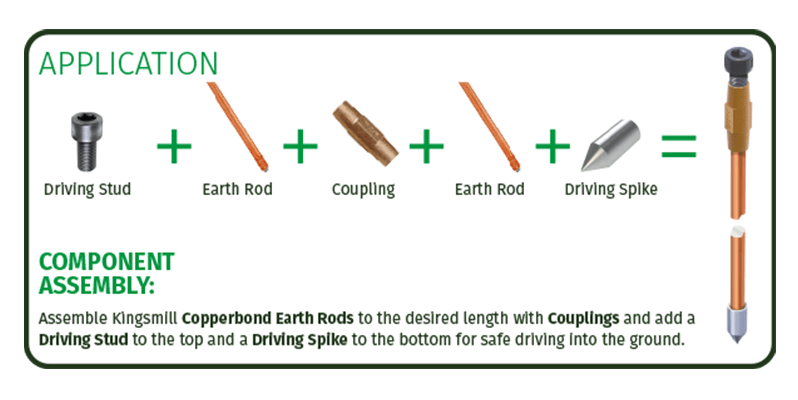

To assemble Kingsmill Copperbond Earth Rods to the desired length with Couplings and add a Driving Stud to the top and a Driving Spike to the bottom for safe driving into the ground. (Refer to “How to Install” tab for further information)

For installing lightning earthing system applications, We recommend the use of Copper earth electrode systems due to their inherent low resistivity and corrosion resistance.

Materials used in earthing systems must be able to:

- withstand mechanical damage,

- resist corrosion,

- provide a low impedance path to earth,

- and carry the maximum fault condition for the application/installation.

For protective earth networks and lightning protection applications our range encompasses:

Copper earth rod, earthing pole, copper bonded ground rod, earth ground rod, earth rod connector, earth rod cover, earth fitting, earthing studs, ground clamps for ground rod, ground pole and grounding post.

Our castings are high quality/high copper content complying to BS 7430 and BS 62561-1. Additional to our range are UL listed copperbond earth rods and exothermic welding.