An effective lightning protection system is mainly composed of two forms (i.e., internal and external) of protection systems, depending on their functionality.

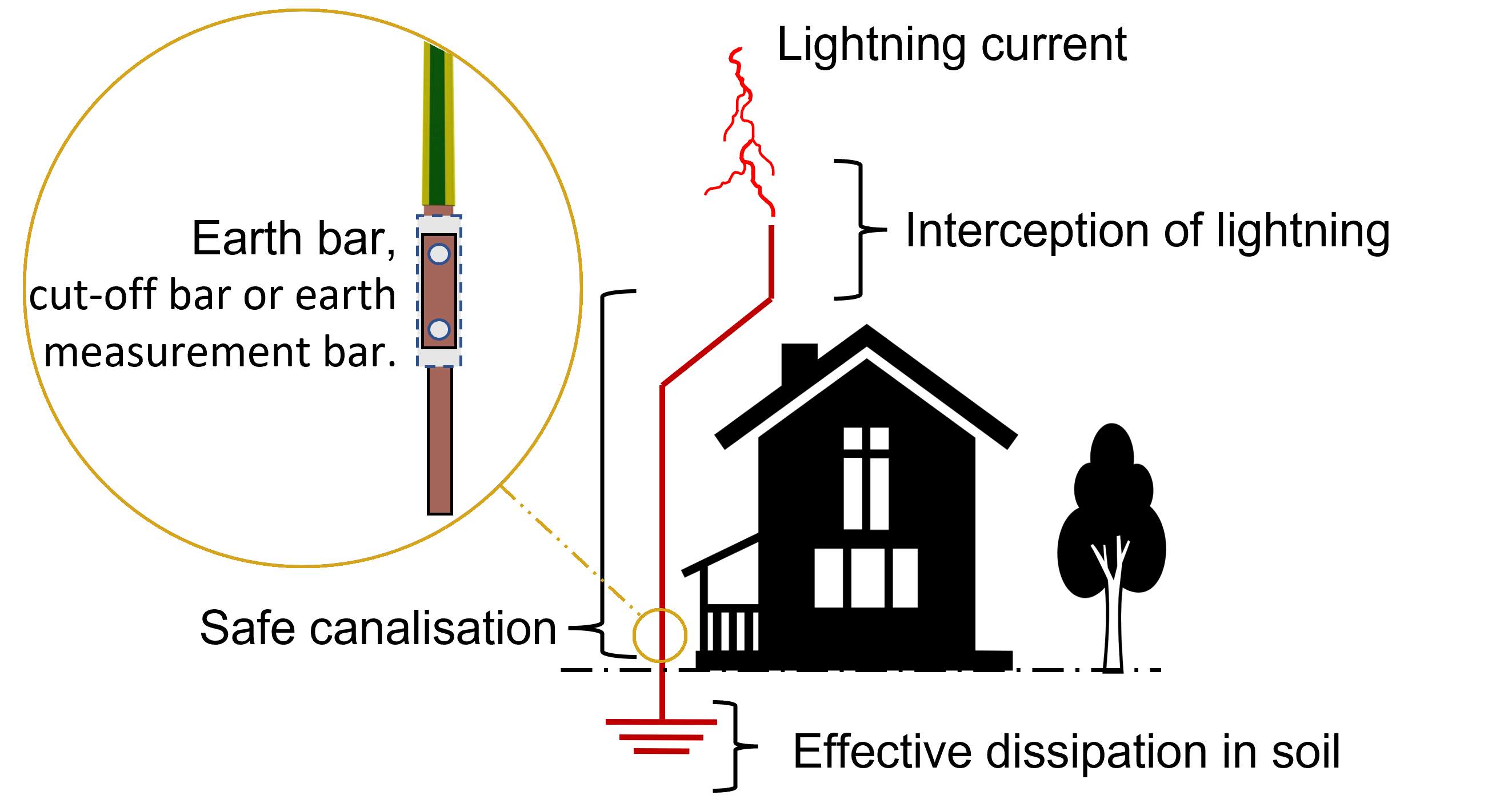

These systems are very important in protecting buildings from damage due to the direct effects of lightning, fire hazards etc., as well as the secondary effects which include damage, often irreparable, to electronic systems. External lightning protection systems include different design methodologies to protect structures or buildings. As well as open areas and people from direct lightning strikes. The purpose of a lightning protection system is to ensure the safety of a building and its occupants in the event of direct lightning strike, providing a safe pathway to the earth to ensure effective dissipation of lightning currents.

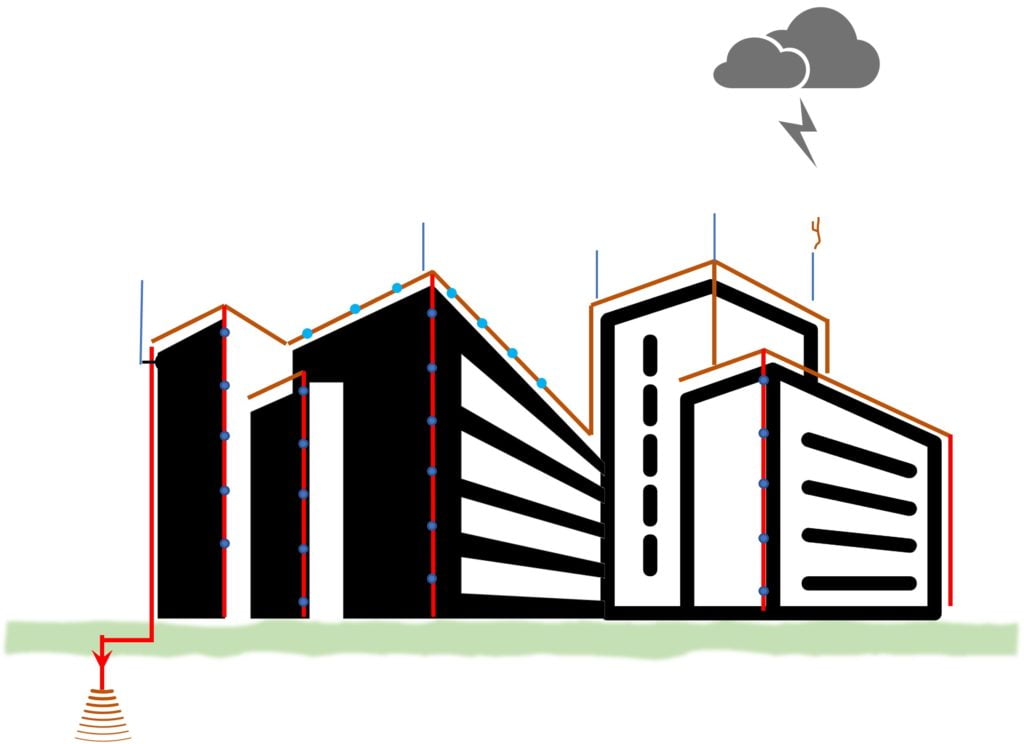

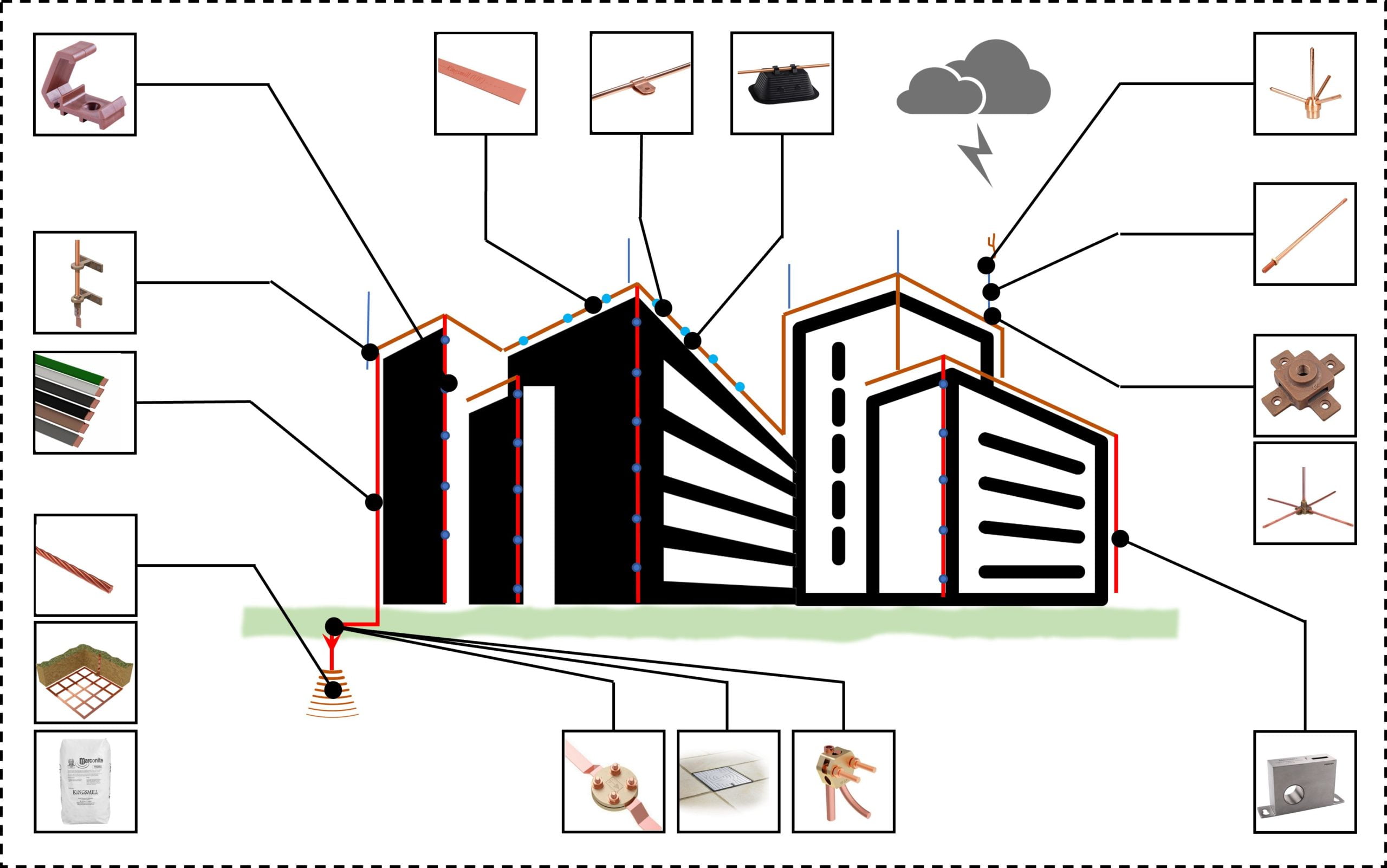

A well-designed system has several elements that are used to ensure efficient protection of the structure. Figure 1 illustrates a representation that groups the key elements of external lightning protection systems.

As shown in this figure, an external lightning protection system is the outer part of the system intended to intercept, safely conduct and provide passage for lightning current to flow to earth. It forms the interception system intended to be the preferred point of impact for lightning. In this figure, a multi-point air-terminal is connected to an elevation rod to attain the desired height for protection; these are combined with air terminal bases or side-mounted rod brackets, Other interception masts may be used, for example free standing air terminals or our groundbreaking lightweight mast. The masts are often connected together using cables and/or tapes, which can also be used to form a mesh of conductors by themselves on the structure. Lightning protection system also requires the use of fittings to fix and secure the conductors to the structure.

Well-positioned down conductors are used to ensure a safe flow of lightning currents to the earth. In some applications, lightning strike counters are installed on the down conductor in order to register direct lightning events passing through the lightning protection system. In most cases, these elements have a long life and do not require a battery or any external power source.

All the mentioned products can be found on our website under their respective categories (Air Termination Network, Conductors and Fittings).

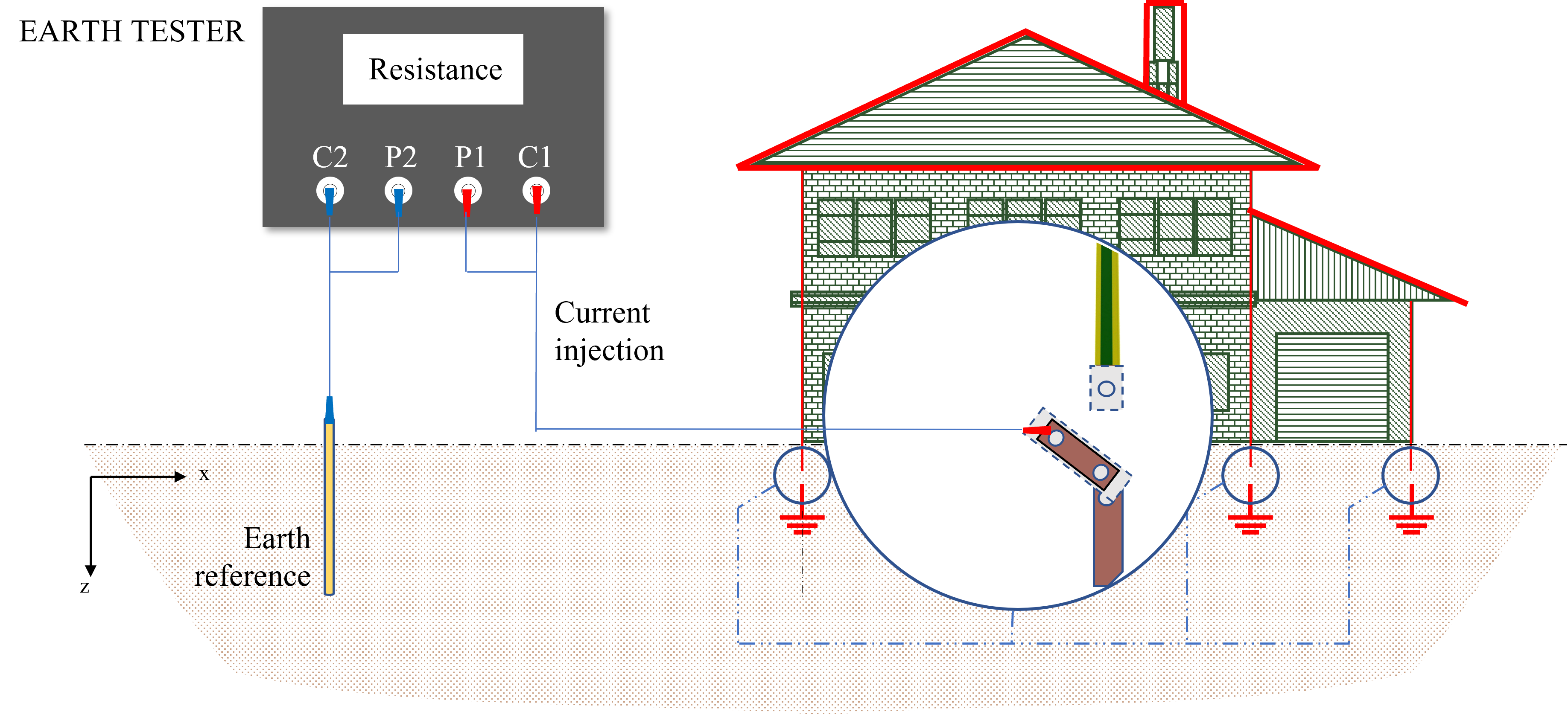

The dissipation of current into the ground is ensured by a well-designed earthing installation. This consists of a wide range of devices such as earth rods, mats in combination with earthing conductors and earth clamps, mechanical joints can be substituted with exothermic welding which forms a permanent, corrosion resistant, safe, simple and quick way to join copper to copper and copper to steel conductors in an earth termination network. A complete guide for this can be found in the KingsWeld exothermic welding process.

It is worth noting that the resistance of the earth-termination should be as low as possible for better dispersion of current into the soil. In some areas of high soil resistivity, it is difficult to obtain a low earthing resistance, and engineers effectively increase the diameter of the earthing system by treating the soil surrounding the system using low resistivity materials, to find out more about achieving this, make sure to have a look at the piece we published explaining reduction of earthing resistance. Finally, inspection pits are used to facilitate testing of the earthing systems. Different types and materials are used for the earth pit according to its location and the nature area.

| BS EN 62305 | Protection against lightning |

| NF C 17-102 | Protection contre la foudre – Systèmes de protection contre la foudre à dispositif d’amorçage |

| UNE 21186 | Protección contra el rayo – Pararrayos con dispositivo de cebado |

| NP 4426 | Proteção contra descargas atmosféricas – Sistemas com dispositivo de ionização não radioativo |

| NFPA780 | Standard or the installation of Lightning Protection System |

In addition to the above standards, each country may apply specific regulations, which must be taken into account for local conditions and regulations.

In this light, Kingsmill, as a leading manufacturer, and supplier of earthing materials and lightning protection products and equipment, offer a wide range of material suitable for various applications, since each system tends to be unique in terms of both material selection and design. Kingsmill additionally offers PVC sheathed conductors in five standard colours to blend in with a building’s aesthetic appearance.

These are also some standards proposed principally for the installation and other standards for the testing and the measurements in the field of lightning protection systems such as the IEEE 81, which provides a guide for measuring soil resistivity, earthing impedance, and earth surface potentials of earthing systems.

The material used in each element should be selected according to its specific application. For instance, there are materials for use above ground and others for underground applications.

There are also standards principally developed for the test and verification of the protection system components, ensuring that only quality products meeting rigorous requirements are used. Other regulations and rules are also proposed for the purpose of management of the project. Among many other related standards relating and making reference to lightning protection, we can cite the following related standards:

- BS EN 62561 – Lightning protection system components (LPSC)

- BS EN 61643 – Low-voltage surge protective devices

- BS 7671 Requirements for Electrical Installations

- UL 96A Standard for Installation Requirements for Lightning Protection Systems

- BS 7430 Code of practice for protective earthing of electrical installations

- UL 467 Grounding and Bonding Equipment

Often, special applications are catered for in a separate way:

- Lightning protection systems of railway systems vehicles,

- Protection of ships against lightning and transients

- The protection of aircraft and offshore installations

- Protection of power and telecommunication lines placed outside the structure, including pipelines.

For all of these reasons, Kingsmill Industries is a brand of choice that is dedicated to serving the needs of its customers.

Lightning protection systems are used on thousands of buildings, homes, factories, towers, and even on the launch pad of the space shuttle.

How do we know if we need to install an external lightning protection system?

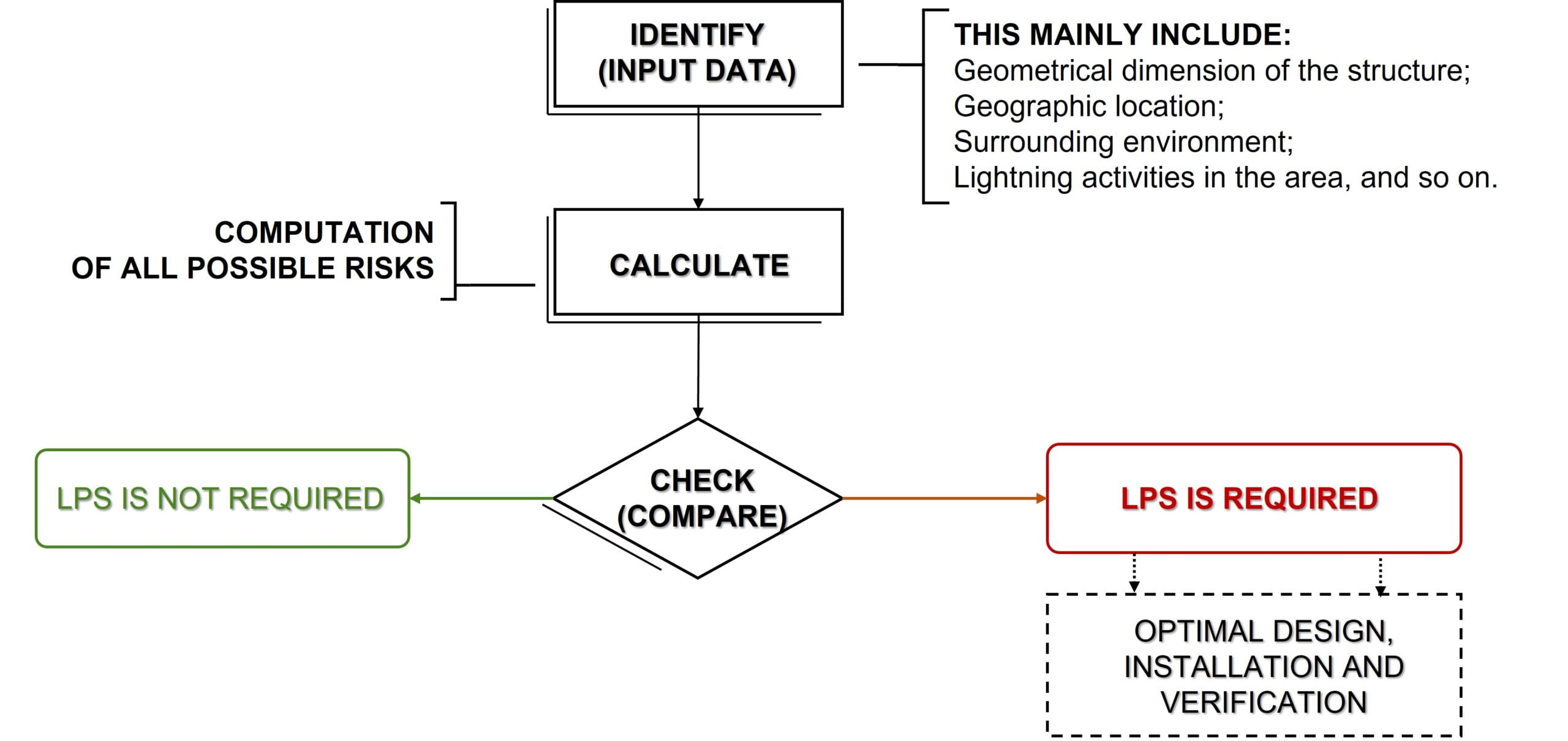

It is well-known that to reduce the loss due to lightning discharge, protection measures are required and specialists in this field should be consulted at the outset. The first step is to carry out a risk assessment, which helps identify the degree of protection required and their associated risk factors. Figure 2 shows a simplified representation of the common steps for deciding the need of protection.

Before designing any new lightning protection system, these should be followed when deciding if any protection measure is required. For instance, the process in Figure 2 provides an example of how to facilitate the risk assessment procedure, and the detailed process which must be followed.

The first step consists of collecting associated data and information relevant to the structure being protected. Such parameters as the dimensions (i.e., height, length and width) and the characteristics of the structure (i.e., windows, balcony, materials, etc.), the connected power lines, the characteristics of the surrounding environment (structure and lines) as well as the lightning earth flash density in the region where the structure and the lines are located.

The next step consists in manipulating these input parameters using complex equations to determine the risk, and as well as the class of lightning protection system that is. It should be noted that the risks to be considered involve different aspects. Including, the risk of loss of a human life and permanent injury which are important considerations. Other risk factors that can be taken into account are :

- Risk of loss of service to the public;

- Risk of loss of cultural heritage;

Each risk is the sum of its risk components, which may be grouped according to the source of damage and the type of damage. The computed risk represents the relative value of a probable average annual loss. If the calculated risk is less than or equal to the tolerable value defined by standards, no protection measures are required. Otherwise, protection measures must be taken to ensure the safety of people and to avoid the disruption of the services.

Besides the need for lightning protection systems, it is useful in most cases to ascertain the economic benefits of installing protection measures. Thus, evaluation of cost effectiveness of protection is also considered by comparison of the costs of total loss with and without protection measures.

Lightning strikes are dangerous events capable of causing catastrophic damage. Consequently, in the design of a structure, an analysis of this risk should always be conducted in order to assess whether it is necessary to adopt suitable protective measures. In order to ensure an effective protection to a structure against lightning, a protection system must be designed in accordance with the relevant standards. The importance of protecting human life together with the advances in electrical technology, have increased the susceptibility of systems to damage and increased the scope for consequential losses.

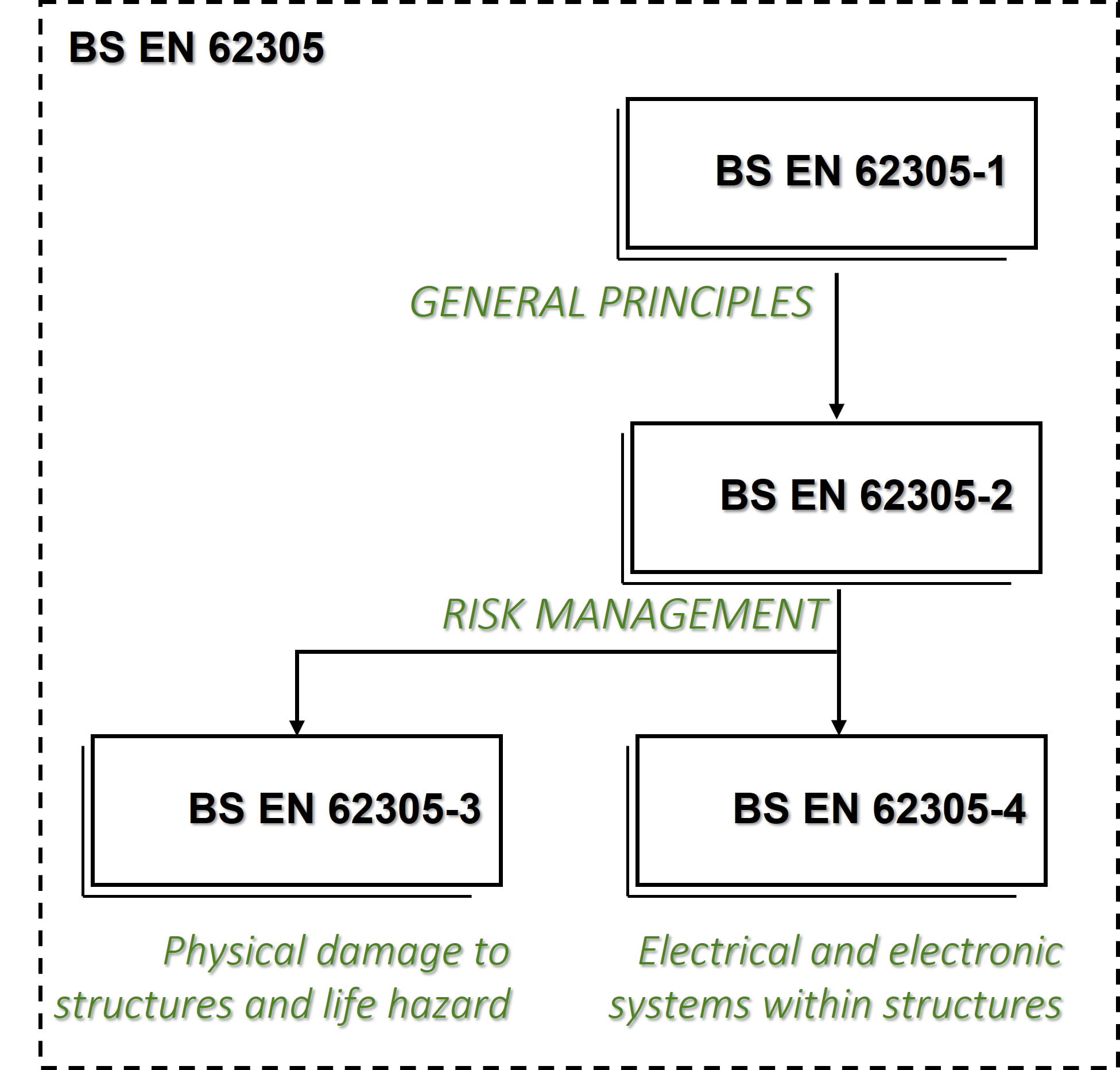

The first part of the standard (BS EN 62305-1: General principles ) gives a general introduction to the entire standard, and summarises the properties of lightning and the factors used to simulate the effects of lightning strikes, including typical procedures for the protection against lightning.

The second document of this series consists of the BS EN 62305 designed for risk management. This part of the standard allows to describe the procedure that allows the analytical quantification of the risk of lightning. This risk can be weighted with respect to the value of the tolerable risk, to decide whether it is appropriate to adopt suitable protective measures. This part of the standard provides the complete framework for the assessment of the risk based on the aforementioned types of losses. Overall, the second part of the standard is an indispensable step toward a correct implementation of the third and fourth parts of the standard.

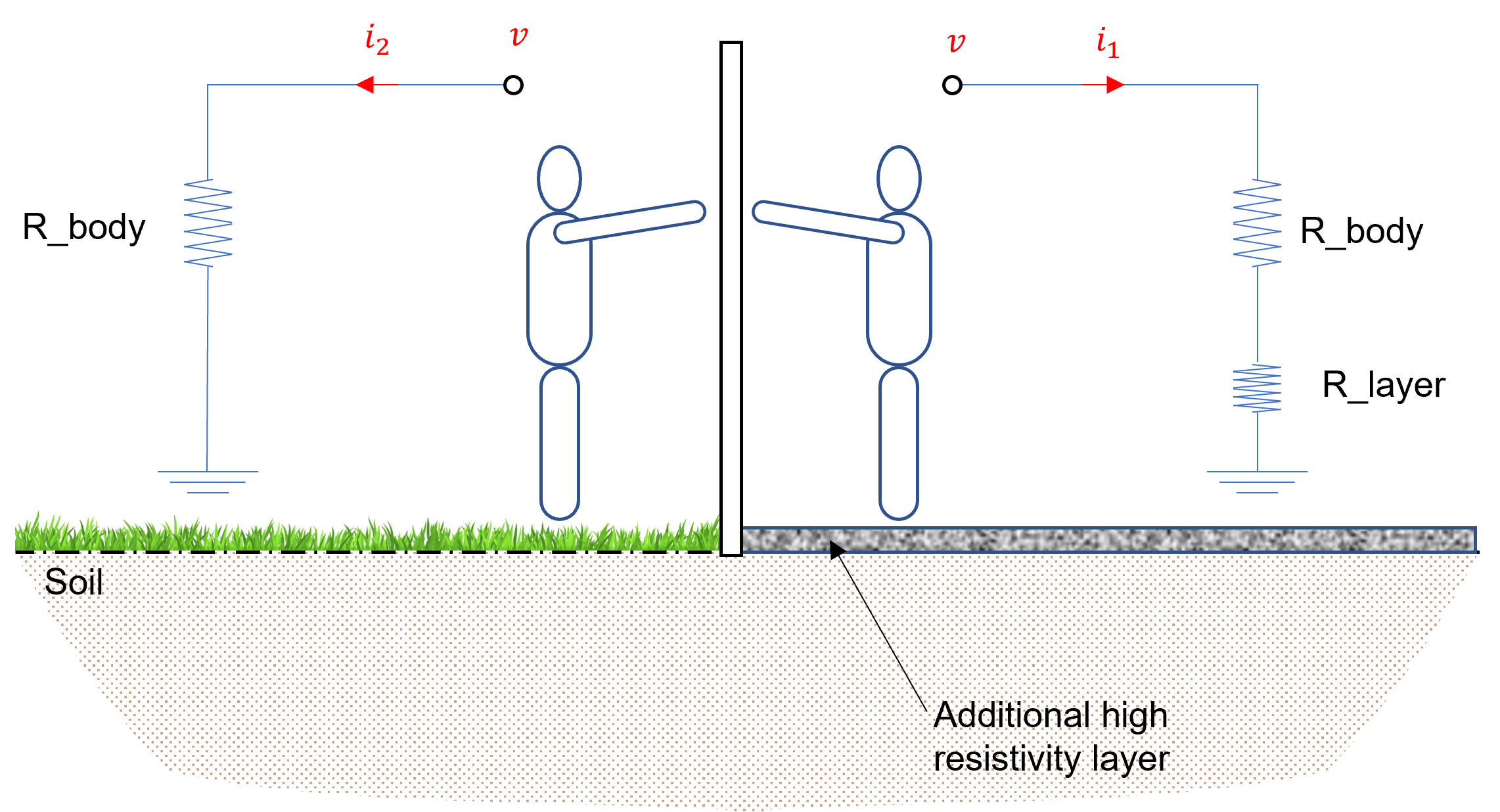

It should be noted that the design of the LPS in this standard is also related to the sources of damage, damage and loss types. Part 3 of the standard, entitled: “IEC 62305-3: Physical damage to structures and life hazard”, deals with the protection of people and structures from physical damage and injury due to touch and step voltages caused due to direct lightning strikes. In particular, this document provides the guidelines to correctly design, install, verify and maintain the external and internal lightning protection systems. The standard also provides the requirements for the implementation of protective measures against damage caused by contact and step voltages.

The fourth and final Part of the standard is the BS EN 62305-4: Electrical and electronic systems within structures. This part provides information on the design, installation, inspection, maintenance and verification of the system of protection measures for electrical and electronic systems in structures, reducing the risk of damage due to the electromagnetic pulses associated with the lightning discharges.

It is clear that the lightning protection system should be installed in a manner where there are no melting or spraying effects except at the striking point. For any given structure, the positioning of the air termination network can be based on different techniques such as the rolling sphere method, the protective angle method and the mesh method. Unconventional protective systems such as early streamer emission and other charge dissipation based-systems are also used in some regions in the world.

It should be noted that the protection may differ from one structure to another according to several factors such as structures containing solid explosive materials or hazardous zones, petrochemical, nuclear plants, etc. In some cases, protection from lightning is achieved by installing an isolated lightning protection system, one where the network of protective conductors and masts is isolated from the structure being protected (for example, in the case of structures containing explosive substances).

A couple of regulations and suggestions can be found in the field of lightning protection such as :

- Soil physico-chemical characterisation is a fundamental step to design effective earthing systems since it is included in the process of material selection.

- The electrically conductive parts of the structure can be used in the lightning protection system to minimise cost and effort.

- The accidental loosening of connections in hazardous areas must be prevented., and continuous supervisions (personnel inspections or using electronic devices) is required for early detection of arising faults.

If you have any questions regarding this piece or require further information, please do not hesitate to contact us through our website to submit a query. We also have an elaborate guides section on our website to provide you with additional resources about lightning protection. To learn more about our products you can download the Kingsmill product catalogue.

[1] IEC Standard, IEC 62305, Protection against lightning, 2012.

[2] NF C17-102, Protection against lightning – Early streamer emission lightning protection systems, 2011.

[3] UNE Standard, UNE 21186, Protección contra el rayo – Pararrayos con dispositivo de cebado, 2019.

[4] NP Standard, NP 4426, Proteção contra descargas atmosféricas – Sistemas com dispositivo de ionização não radioativo, 2013.

[5] National Fire Protection Association, NFPA 780, Standard for the installation of Lightning Protection System, 2014.