People often ask us for a simple explanation of what lightning protection is and how the need for it is determine

The idea that lightning doesn’t strike the same place twice is a long-held belief; however, this is very far from the truth. In reality, lightning can and will strike the same area repeatedly.

Lightning strikes account for some of the most common insurance claims due to the severity of the damage they create. Which is more often than not, due to a lack of a lightning protection system in place, improper risk assessments prior to LPS installation, or simply due to using low-quality components within the lightning protection system.

How Are Lightning Protection Systems Assessed?

To ensure adequate protection Kingsmill uses the International Electrotechnical Commission (IEC) series of standards. These were adopted as a European Standard (EN) and therefore as a British Standard (BS).

A well designed lightning protection system (in accordance with BS EN 62305 parts 1 to 4), starts with a comprehensive risk assessment that not only studies the design of your structure, but also takes into account the potential sources and types of damage, as well as the potential types of loss.

The risk management procedure in BS EN 62305-2 calculates the risk of damage from a lightning strike and provides the basis that is used in parts 3 and 4 for making decisions concerning the materials to be used, as well as their application.

Several factors are taken into consideration to assess the level of protection required. These include:

- Loss of human life, service to the public and cultural heritage

- Lightning flashes to or near the structure and to services connected to or near the structure

- Possible damage – injury to human beings, physical damage and failure of electronic systems

- The physical dimensions of the structure

- The impact of overhead and buried cables entering the structure

- The type of structure, its construction, as well as its use

- Lightning activity in the area (flash density)

- Risk of fire

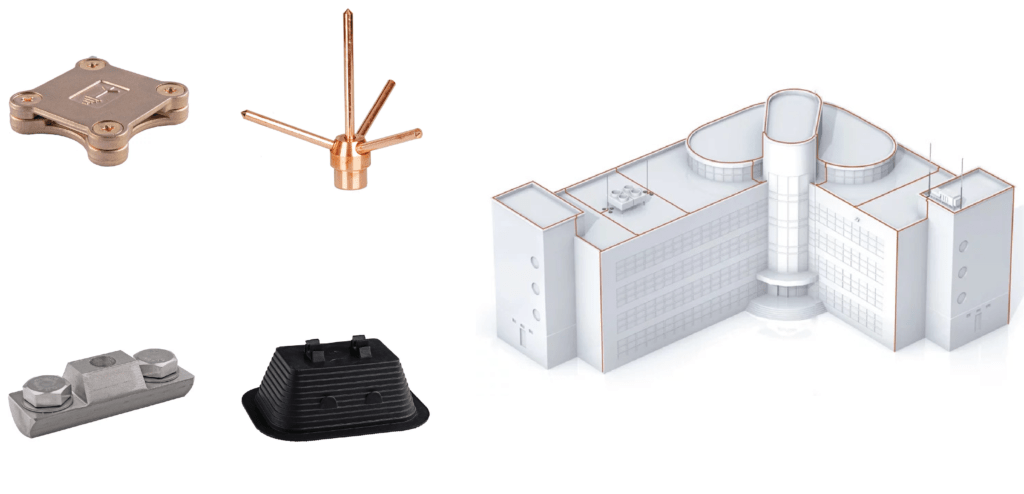

What Are the Main Components of a Lightning Protection System?

When it comes to deciding what methods and materials are to be used, the designer would refer to BS EN 62305 parts 3 & 4.

In essence a lightning protection system includes several internal and external parts that work in unison to prevent damage from lightning.

The key elements are outlined below:

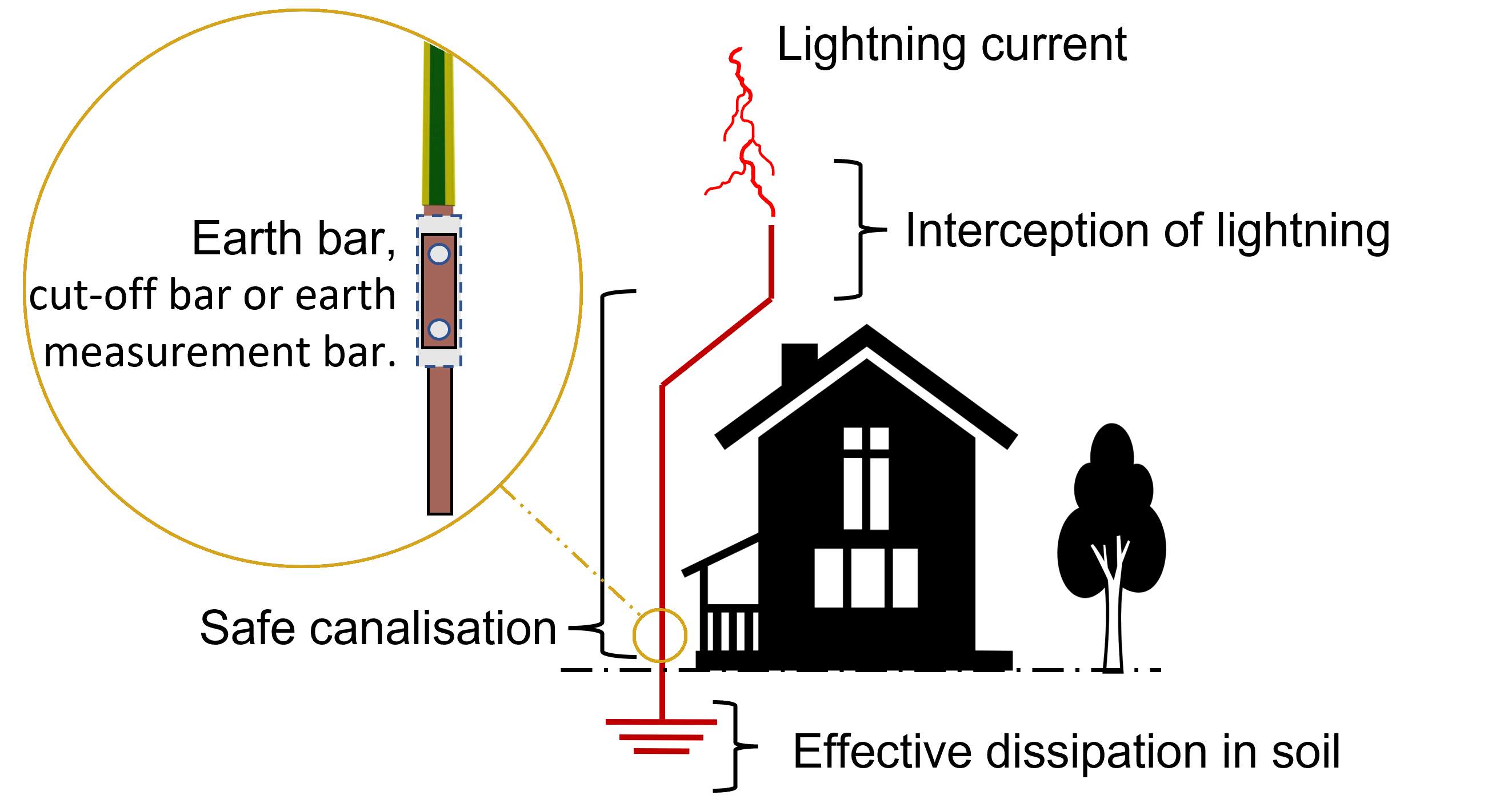

Air Termination

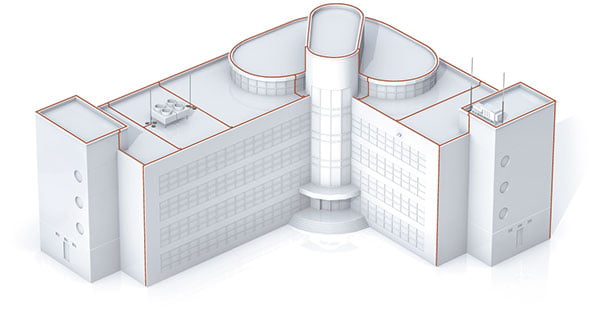

The process of intercepting lightning begins with the air termination network. The air termination network dissipates the lightning discharge by presenting itself as a means through which the lightning current can flow safely to earth. Thus minimising damage to your building and its contents (structural lightning protection)

BS EN 62305-3 provides the designer with a number of methods that can be used to determine the placement of the air termination network on your structure. These can be used in connection with each other and are:

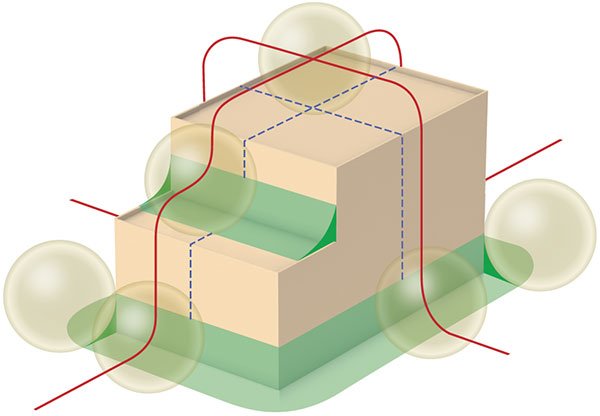

- Mesh system

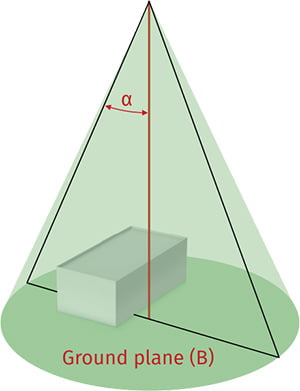

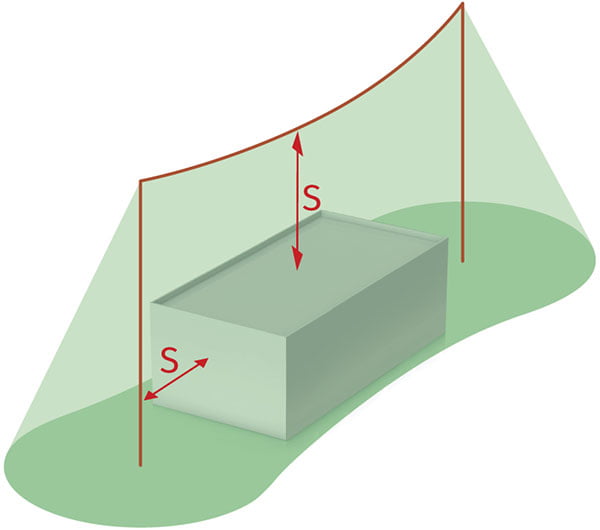

- Rolling Sphere

- Protective Angle

So, for example, on larger structures a combination of conductors, masts and terminals might be used in a mesh system. Whereas simple structures or items of roof mounted plant (like a chiller) might use one or more air terminals/masts to provide protection under the protective angle method.

Kingsmill offer comprehensive range of Lightning Protection Air Terminals, Lightning Interception Masts, and conductors for successful implementation of an effective air termination network.

Down conductors are an integral component of a lightning protection system in that they carry the lightning discharge safely to the ground (by providing a low impedance path from the air termination system to the earth system).

Down conductors must be:

- Sufficiently robust to resist mechanical damage

- Able to resist the effects of corrosion

- Placed with equal spacing around the building perimeter where possible

At Kingsmill Industries, our comprehensive range of PVC sheathed conductors enable lightning protection designers greater freedom to aesthetically blend conductors into the building facade. Our full range of conductors that can be used in both air termination and down conductor networks is as follows

- Copper Conductors: We offer bare, tinned and PVC sheathed. The benefits of copper are its inherently low impedance and its corrosion resistance. This later feature combined with the high value of copper, makes it prone to theft!

So, we also offer lower cost alternatives for above ground use –

- Aluminium Conductors: combine the benefits of lightweight and easy installation. Such materials exhibit little “spring back” and so are easier to dress to the contours and shapes of the structure.

- STRIKEBAND Conductors: combine the corrosion resistance and inherent low resistivity of copper with the lightness and flexibility of aluminium, providing a cost-effective, easy to use alternative to solid copper.

When deciding which conductor to use the following might be taken into account

- Solid Circular Section Conductors: are the easiest to install since they can be bent through any plane (360º), whereas tape can only be bent in two directions. In addition, 360º overcomes problems that are presented by buildings with complex geometry.

- Rectangular or flat tape conductors can only be bent through one plane, but are easy to dress to flat roofs and walls

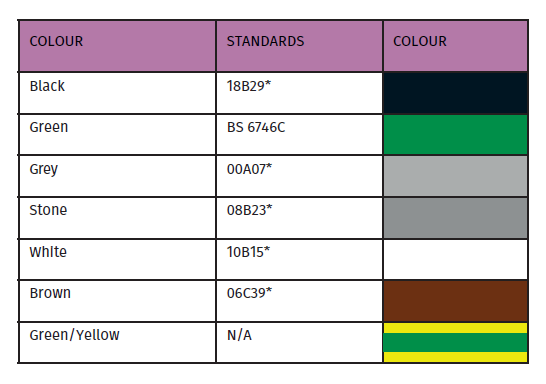

- PVC-Covered Conductors in Aluminium or Copper: provide an aesthetically pleasing product. We offer a range of colours designed to match commonly used building materials. The PVC sheath also acts as additional corrosion protection for aluminium conductors.

Air Termination Network Usage Scenarios:

Copper: Expensive, but the best impedance and corrosion resistance.

Aluminium: Easy to install, commonly used in most UK, Europe, North America, and Asia installations.

Strikeband: Offering a balance of corrosion resistance and ease of installation.

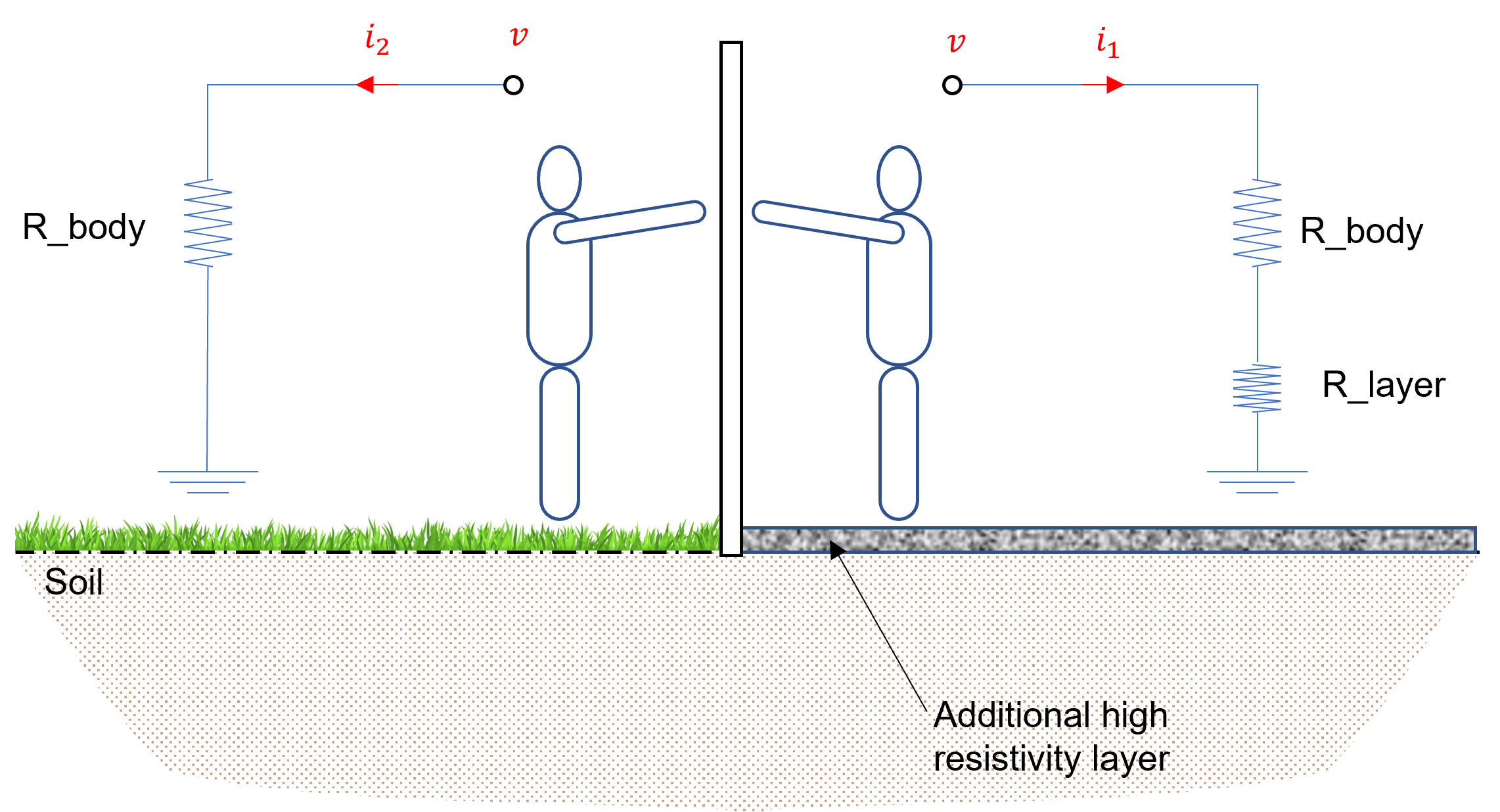

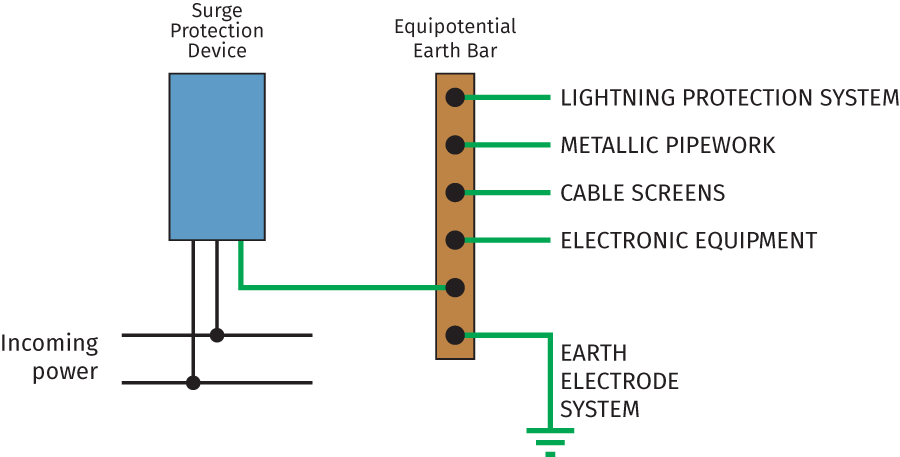

Equipotential Bonding

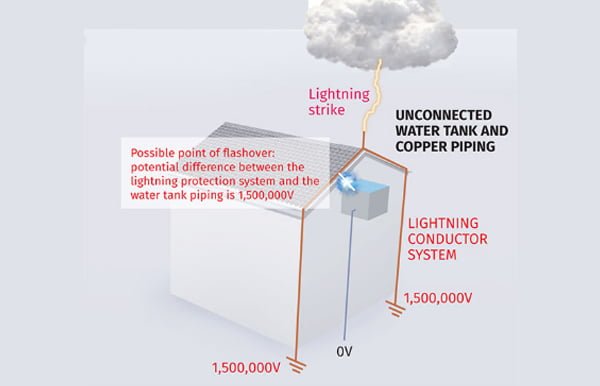

An important aspect of a Lightning Protection System (LPS) is that electrically continuous parts of a structure must be bonded into the lightning protection network. The purpose of this bonding is to ensure that, in the event of a lightning discharge, any sparking or flashover of the lightning current to conductive parts of the structure, for example, water pipes, cables, etc., is avoided.

In most structures, there are typically a number of services other than electrical supply that employ metallic connections in their design.

To eliminate indoor risks during a storm, equipotential bonding must be carried out to link all metalwork and conductive items to have the same potential with respect to earth, this can be done through the use of earth bars and isolating spark gaps.

Electrical and data lines can be equipotentially bonded through the use of Surge Protection Devices or Lightning Current Arrestors.

Materials that can provide a low impedance pathway and may require physical bonding into the lightning protection system include:

- Cable screens

- Metallic pipework

- Metallic handrails, stairways, screens

- Structural steelwork

- Reinforcing bar

- Ductwork

- Supporting structures for curtain wall systems

- Metallic cladding systems for buildings

Kingsmill Industries offer a wide range of bonding solutions:

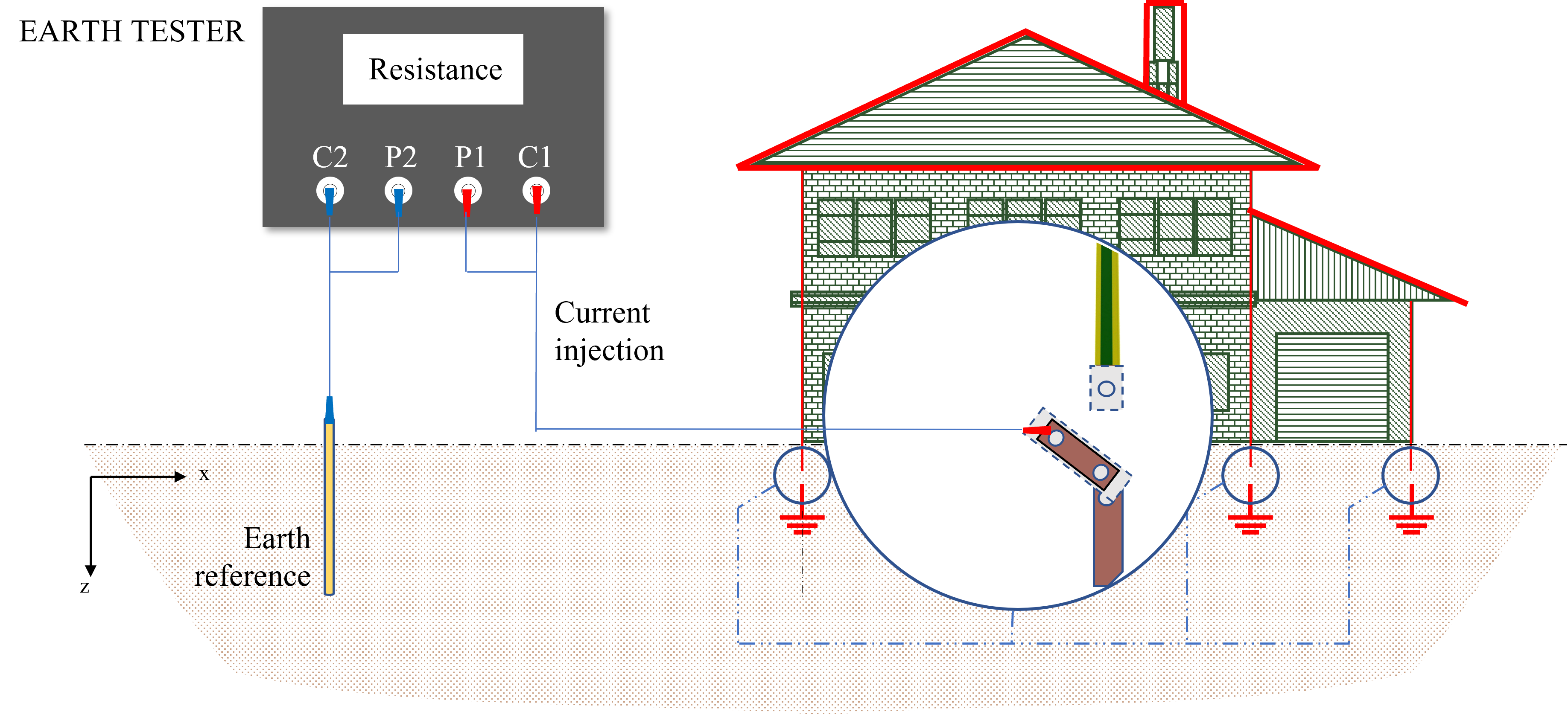

Earthing System

Earthing, also known as an earth termination, is a crucial component of any lightning protection system.

The purpose of an earth termination network (earthing system) is to provide a low impedance pathway for lightning discharge currents to dissipate into the ground safely.

An earthing network should be designed to provide a low resistance path to the earth, typically as per IEC/BS EN 62305 standards which recommend being below 10 ohms.

To help achieve this, Kingsmill Industries supply many high-quality earthing components designed and tested in accordance with the BS EN 62561 series of standards. These ensure a safe, reliable, and low resistance connection for conductors and earth electrodes.

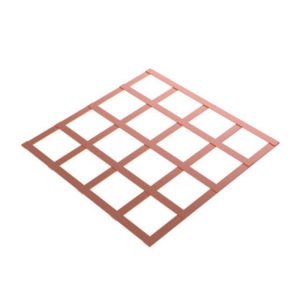

Typically, an earthing network will consist of a minimum of two earth rod positions, but can also utilise lattice earth mats or bare stranded conductors.

For applications where resistance levels in the soil are high, these can be improved by:

- Connecting earth electrodes with ring conductors

- Using copper earth mats and earth plates

Using soil conditioning agents or conductive aggregate (Marconite) to improve conductivity. (Also commonly referred to as Ground Enhancement Material (GEM)).

Surge Protection

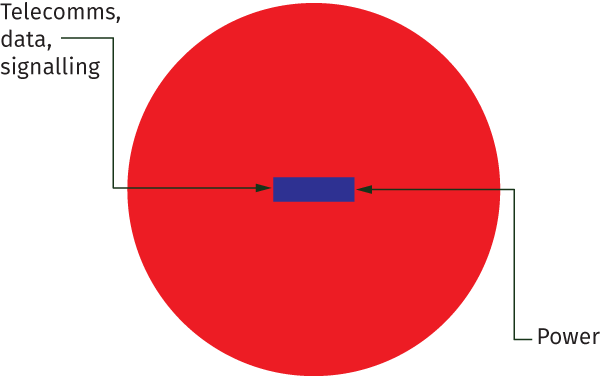

Did you know that during lightning storms, transient overvoltages resulting from lightning, up to 1km away, can damage electronic equipment connected to a power network.

2km target for the impact of lightning around the structure

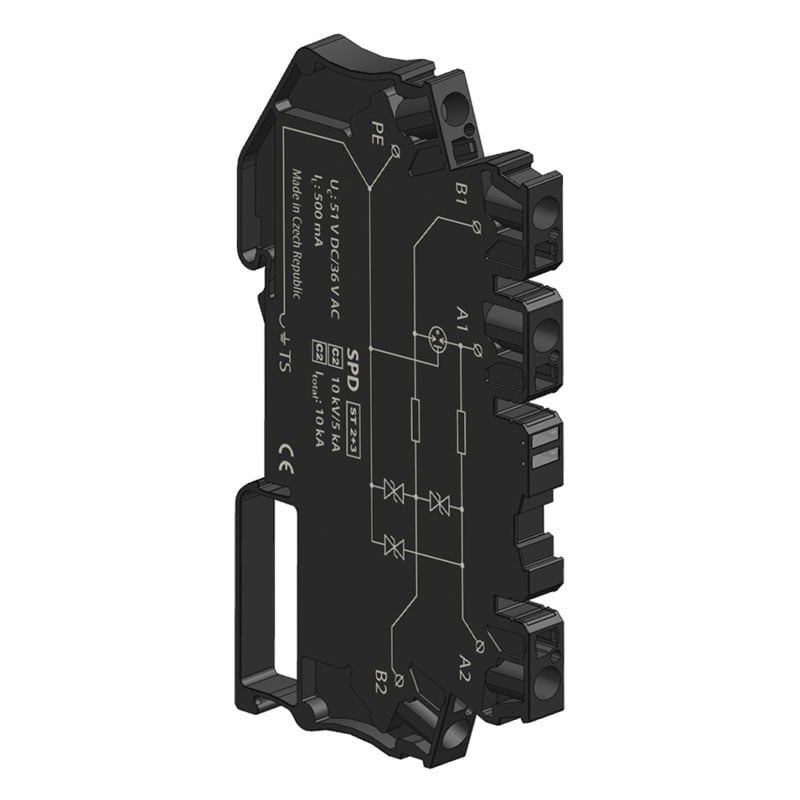

To prevent this, surge protection devices (SPDs, also known as lightning arresters) should be added to conductors entering and exiting the building. This provides complete protection for your electronic equipment from lightning induced transients travelling along electrical and communication cables, as well as data lines

Surge Protection Device Types

Kingsmill provide three main types of mains power lightning protection SPDs. They are classified according to the location in which they are installed.

- Combined Type 1 & 2: Main distribution board

- Type 2: Sub distribution boards

- Type 3: Final circuit protection located close to terminal equipment

Kingsmill Industries offer a range of surge protection devices that can be used in conjunction with BS EN 62305-4 and which have been tested in accordance with EN 61643-11 (mains power); EN 50539-11 (photovoltaic); EN 61643-21 (data/communications).

Final Words

A lightning protection system encompasses a wide range of external and internal elements and components that work in tandem to achieve a singular purpose. From air termination to earthing and everything else in between, Kingsmill Industries is always ready to assist you in finding the best solution that fits your needs.

Check out our full catalogue of industry-tested solutions on our website.

Or call or email us for any additional information you might need to help you with your earthing and lightning protection systems.

If you have any questions regarding this piece or require further information and professional assistance, please do not hesitate to contact us through our website to submit a query.