Numerous standards and regulations have been proposed in order to guarantee the safety of people and the installation of electrical appliances. In fact, electrical shock, known as electrocution, is at the top of the list of domestic accidents.

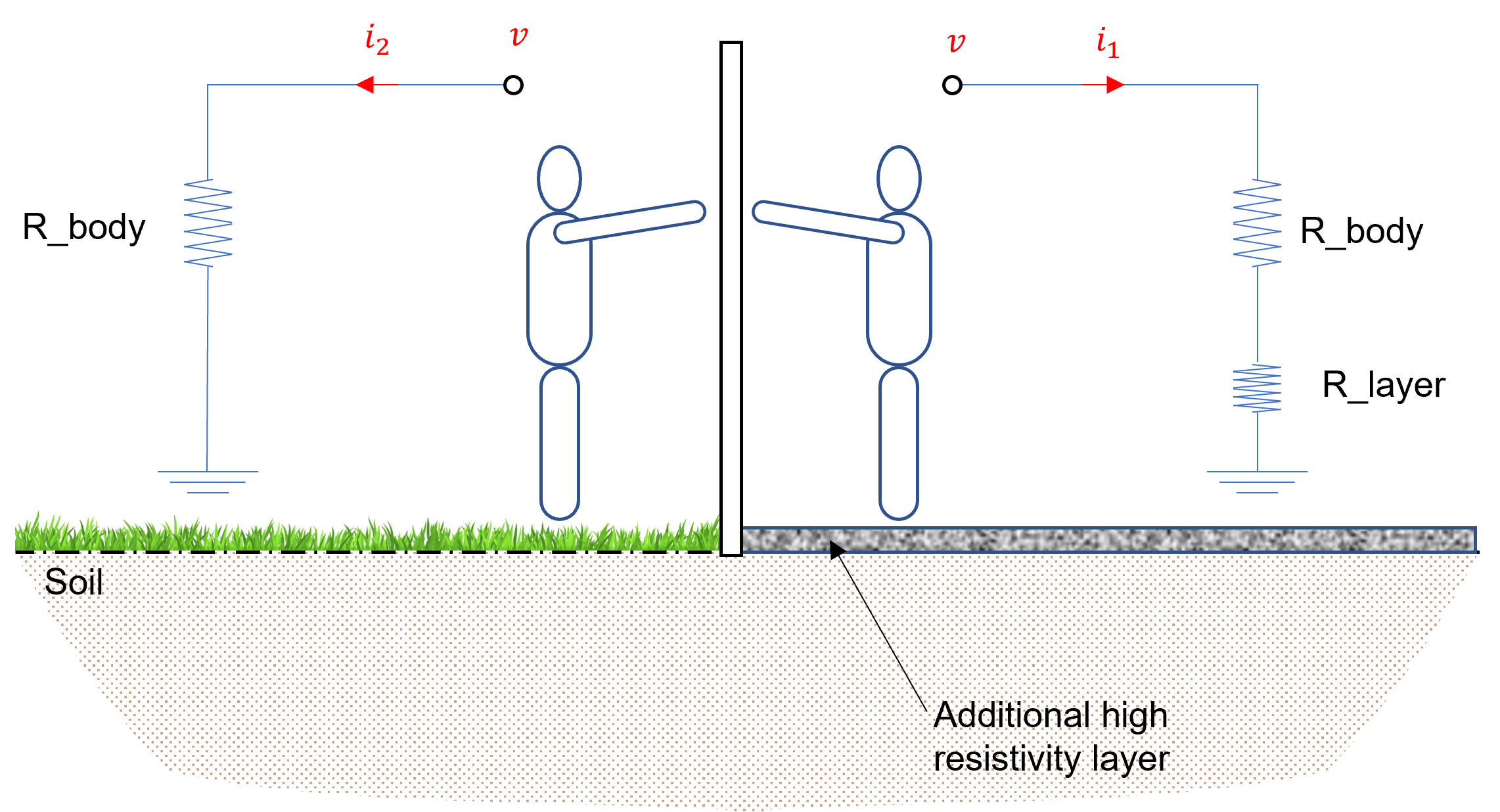

In principle, the safety of people against these electric shocks is based on the combination of a main protective system (protection against any possible direct contact) and additional protection measures in the event of a fault. The latter is used for the protection against indirect contact, and ensured by the combination of an earthing system and protection by automatic power cut-off (e.g., differential protection).

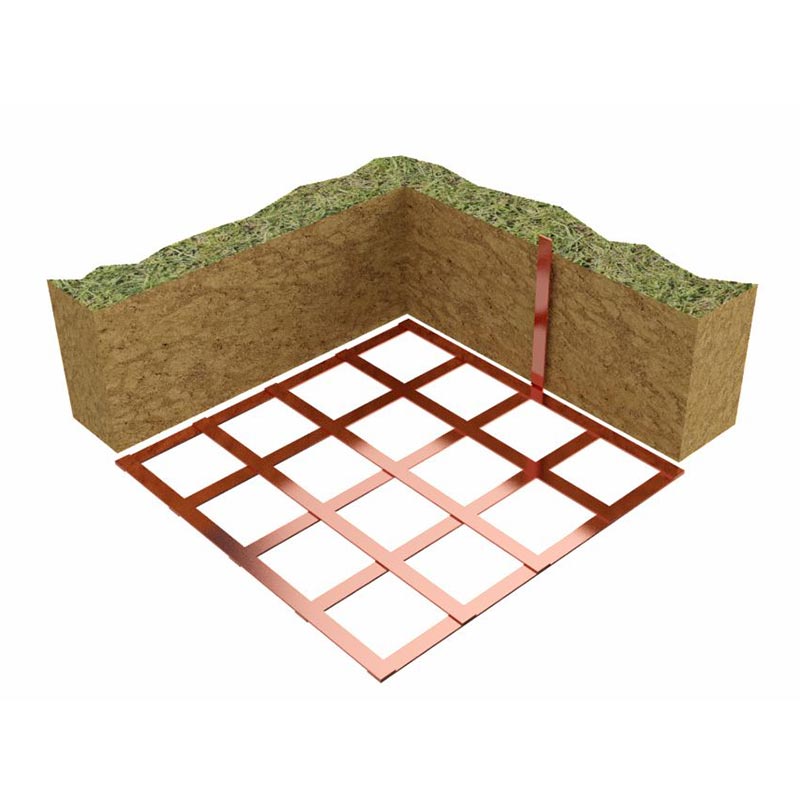

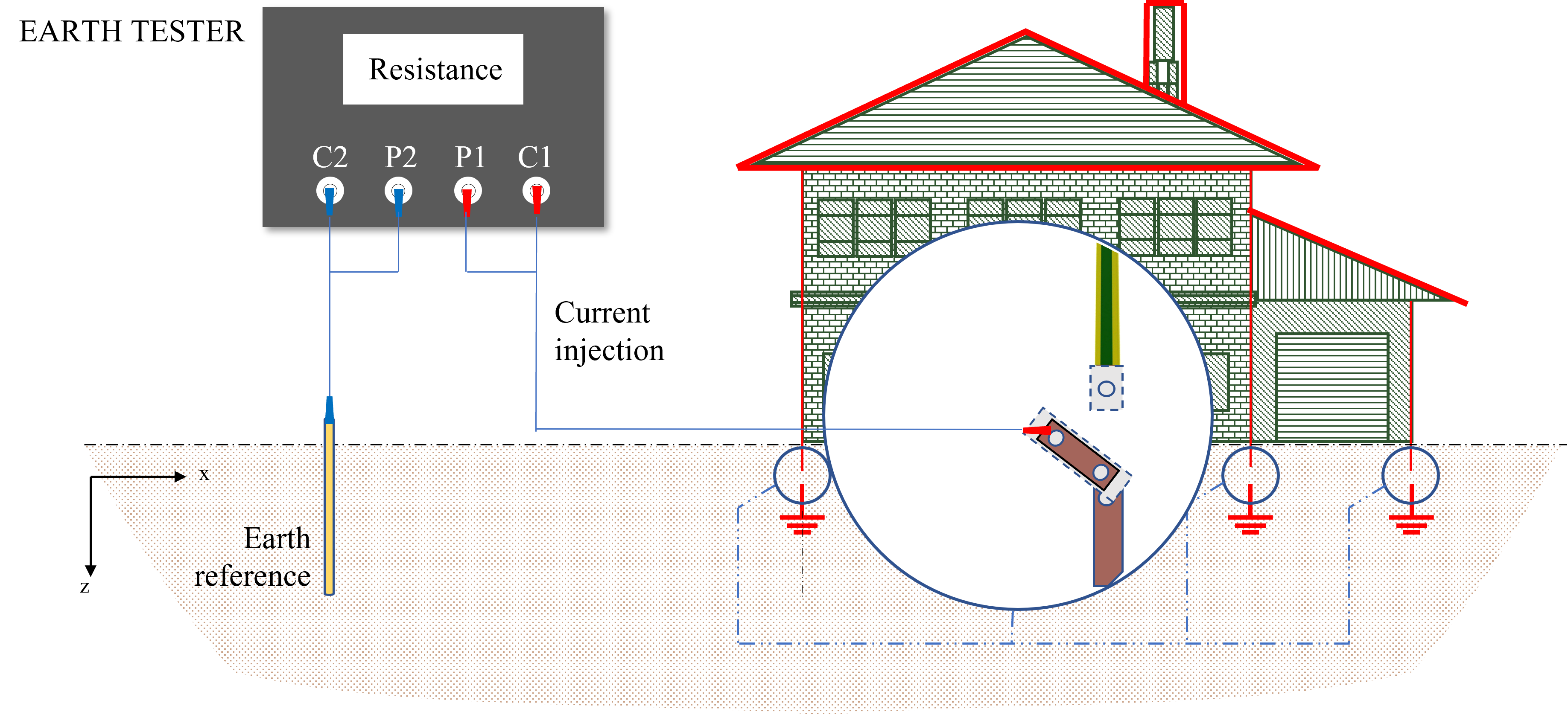

Installing earth rods, earth grid, ring conductor or any other combination of conductors, there are several earthing techniques that we can use. Figure 1 shows three examples of components widely used in earthing systems.

Earthing is an important component of an electrical system because of reasons such as the safe dissipation of undesired currents into the soil. In addition, earthing allows other protective systems to operate effectively. For instance, it allows the circuit breaker or residual‑current device to protect you if there is a fault in your electrical installation where you could get an electric shock should you touch an energised metal part.

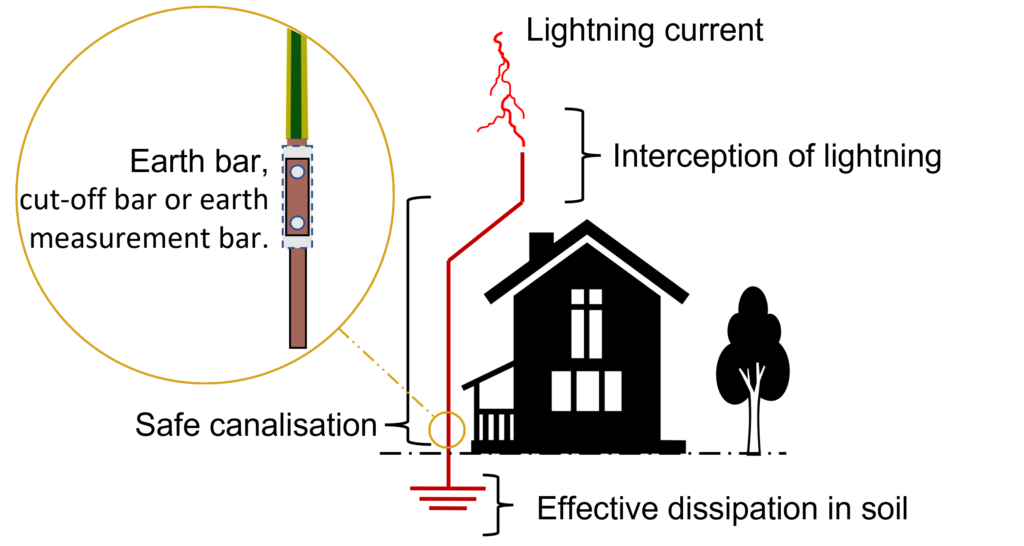

Indeed, earthing systems remain the first thing to consider when creating any electrical circuit or when wanting to protect any installation or system. It is also important in terms of protection against lightning discharges – direct and indirect effects of lightning.

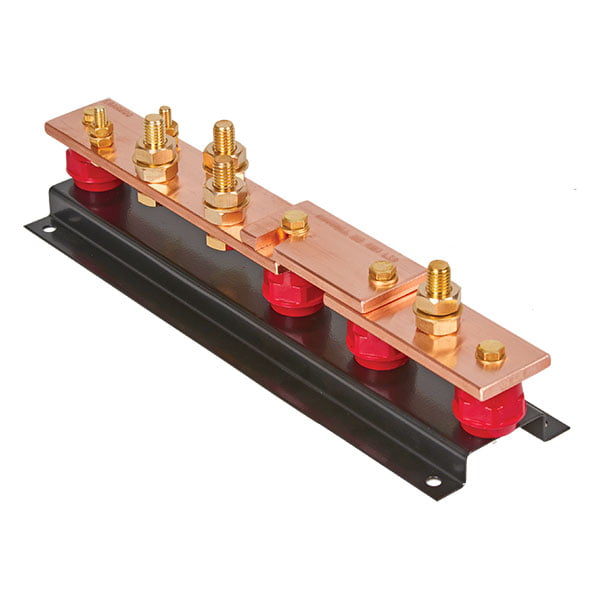

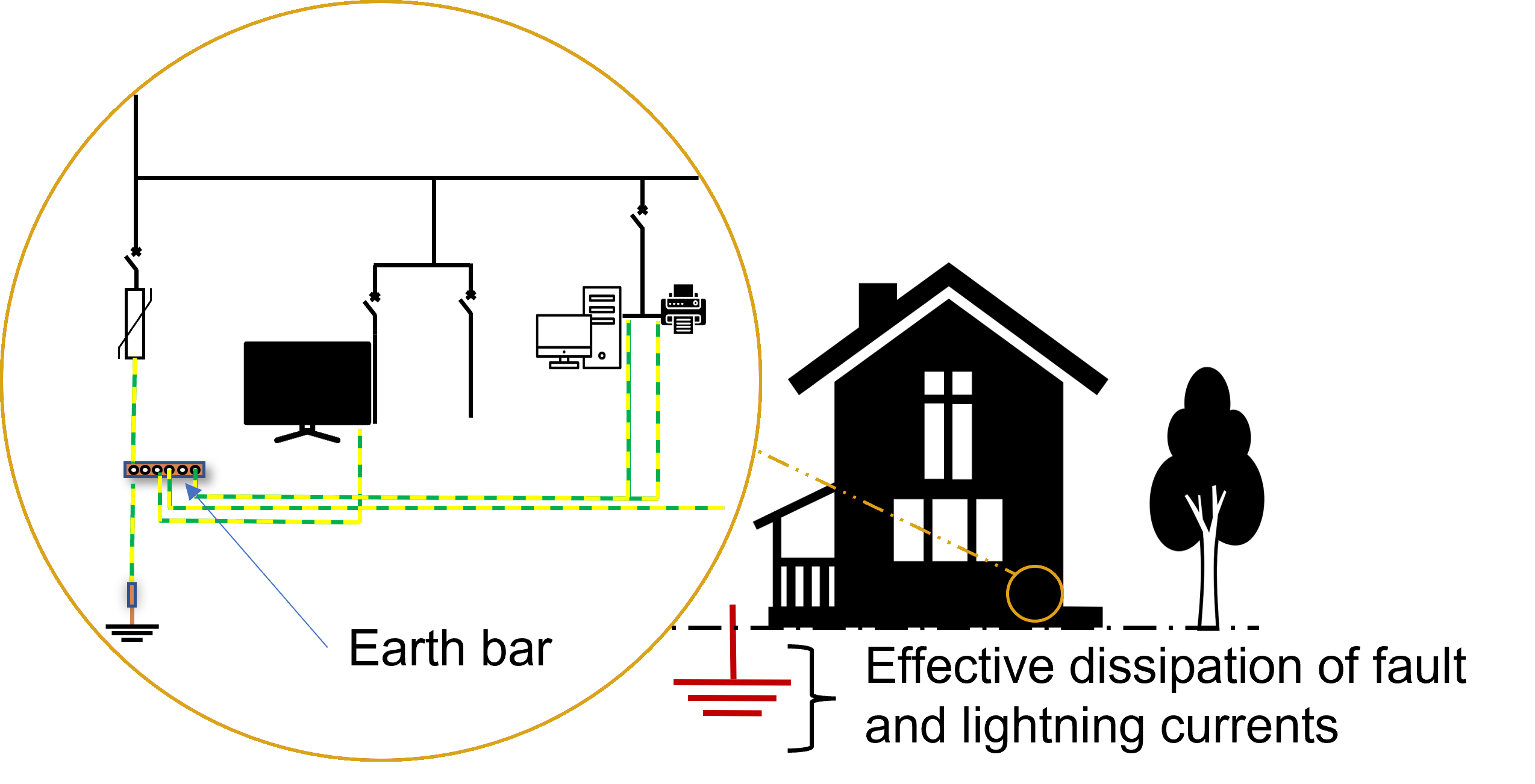

In a well-designed system, all conductive components and services, such as water and gas pipes, power, telecommunications and data cables would be connected to a single earth bonding bar (equipotential bonding). Which, in turn, would be connected to the earth termination system as represented in Figure 2.

Equipotential bonding can be achieved through direct connection utilising bonds, clamps and conductors which link the various metallic services and parts of the structure to earth bars. In this situation, earth bars act as collection points for the various bonds and their subsequent connection to the earthing system. Thus, it can be called equipotential earth bar with regard to its role in this example.

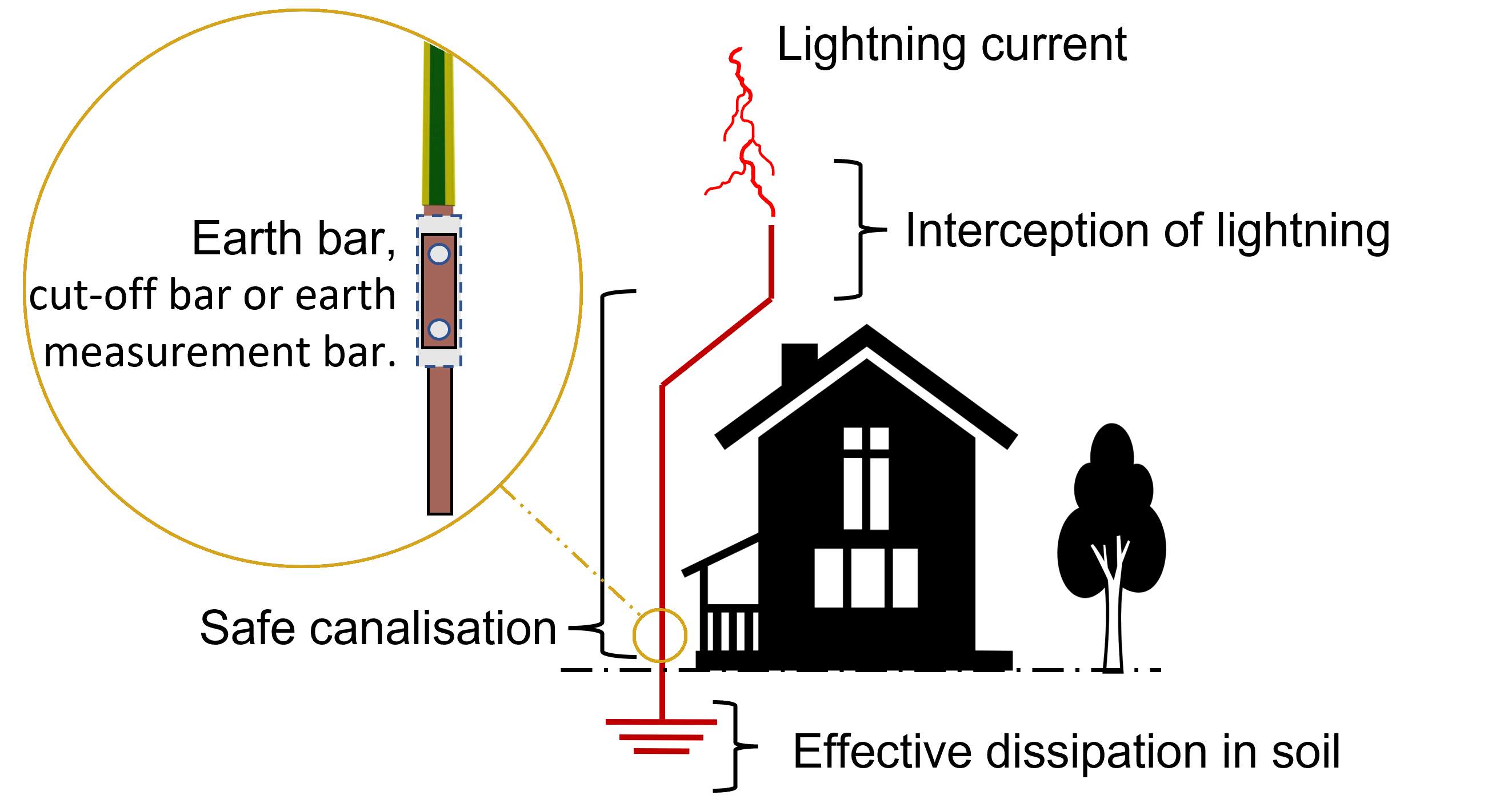

In the same context, we can also find earth bars in lightning protection systems as shown in Figure 3. In fact, lightning protection earthing systems are often segregated from power earthing, but might be bonded under specific circumstances.

The first important piece of information to know may be the position of the earth bar in earthing systems. Normally, it is located between the earth-termination system and the electrical panel distribution block in the internal protective systems. As shown in Figure 3, the earth bar is an electrical connection located between the down conductor of the external lightning protection system and just before the earth termination system.

In both cases, the earth bar position is selected in order to help engineers to make a cut in the circuit for measuring the resistance of the earthing installation, checking the effectiveness of the protective earthing system. For this role, it is also called a cut-off earth bar or earth measurement bar.

An earthing bar is too simply a solid metal plate with multiple holes to which wiring is connected to using crimp lugs and bolts. Regarding the variety of roles that it can play, Kingsmill Industries have offered several designs to meet the requirements of the protective systems in any given installation. Figure 4 illustrates three different earth bars.

Outgoing way:

Outgoing ways enable the earth connection to be isolated from the test link.

Standard link:

Standard test links are supplied on all Kingsmill Earth Bars unless outgoing ways are requested

Parallel and Staggered Fixings:

Parallel and staggered fixings are typically used when there are space restrictions impacting on the installation of the Earth Bar.

Fixings and No-fixings:

Earth Bars can be supplied with and without fixings. In addition, options include punched holes, tapped holes or plain bars.

Our high-performance range includes standard, single-linked and twin-linked Earth Bars and can also be manufactured to your own specifications.

Kingsmill Industries supply all earth bars on metallic bases. We can also supply galvanised and hot-dipped galvanised bases for use in external or more humid environments.

Want to know more about earth bars? Check out our guide.

For any further questions, please don’t hesitate to reach out to us at [email protected]. Or contact us through our website to submit a query.